Ensuring miner safety in challenging environments of the mining industry is where the perils range from heavy machinery operations to navigating confined underground environments paramount. The risks inherent in mining not only threaten worker safety but can also lead to significant operational and reputational setbacks.

This is where Computer Vision, also known as Vision AI, steps in, heralding a new era in mining safety. Tailored specifically for the unique demands of mining operations, Vision AI employs advanced Artificial Intelligence to enhance safety measures. With real-time surveillance and automated hazard recognition capabilities, Vision AI transforms traditional safety methods into proactive, intelligent strategies. These innovative tools offered by Vision AI redefine the safety standards in mining, focusing on protecting workers and fortifying operational security.

The Importance of Safety in the Mining Industry

In mining, safety protocols are vital for worker protection and economic stability. With its deep underground operations and heavy machinery, this high-risk industry requires stringent safety measures. Safety lapses carry a severe human cost, including injuries with lasting impacts and emotional strain on workers and their families.

Economically, the fallout from insufficient safety is substantial, encompassing costly operational shutdowns, lost productivity, higher insurance rates, and potential legal repercussions. Additionally, a company’s reputation can suffer, impacting investor relations and market standing.

Let’s closely examine the On-the-Ground Reality with Data

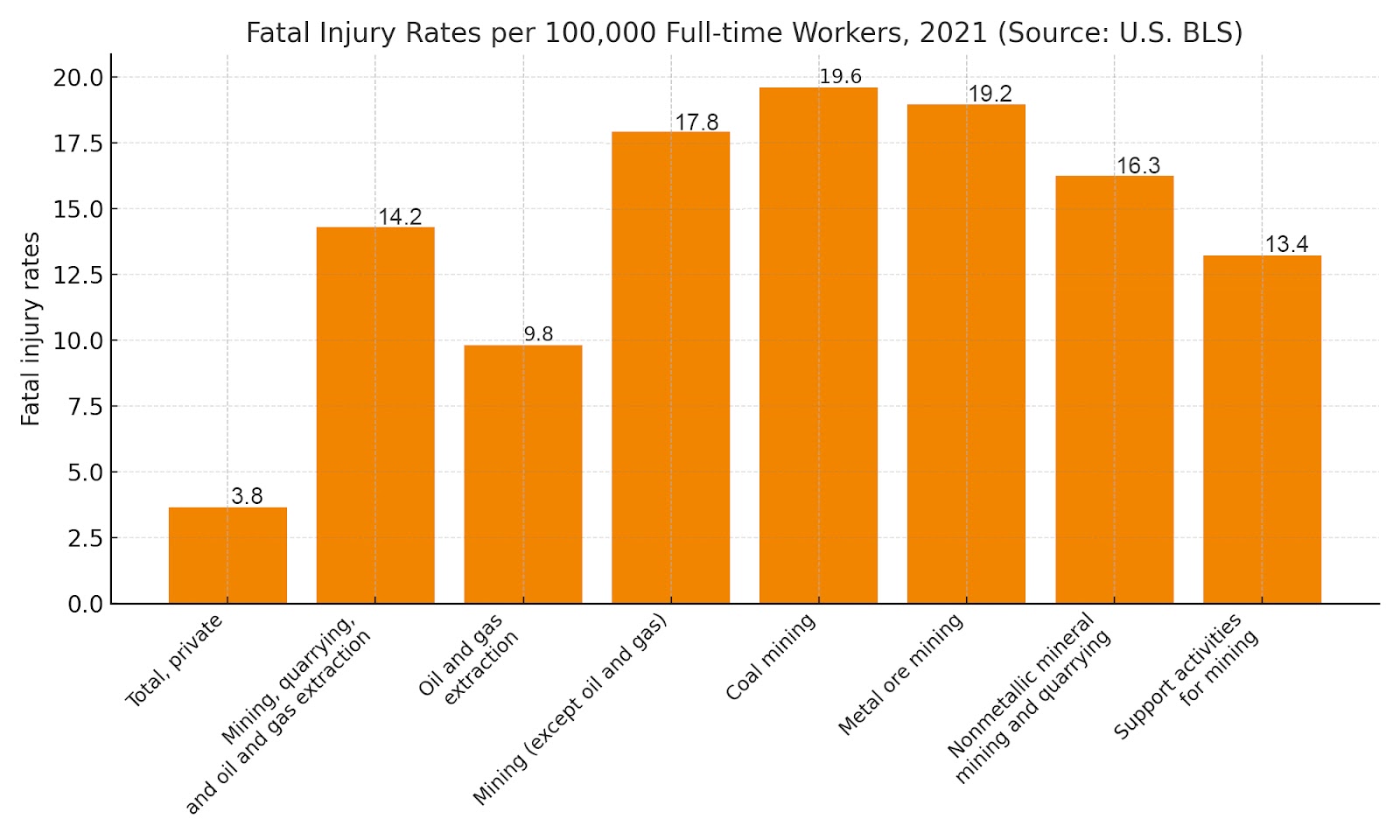

The U.S. The Bureau of Labor Statistics shows a 21.8% rise in fatal injuries in mining, quarrying, and oil and gas extraction from 2020 to 2021, increasing from 78 to 95 fatalities in the country alone.

The mining industry’s fatal injury rate was 14.2 per 100,000 workers, significantly higher than the private industry’s average of 3.8. Notably, coal mining’s rate was 19.6, and oil and gas extraction was 9.8 per 100,000 workers, indicating heightened risk in these areas.

Source: U.S. Bureau of Labor Statistics

These statistics underline the urgent need for adequate safety measures in mining. Safety lapses bear-human costs and economic consequences, leading to operational issues, legal and insurance expenses, and reputational damage. Enhancing safety in mining is, therefore, ethically and economically crucial.

Thus, robust safety strategies in mining are essential. This entails ongoing risk evaluations, safety training, the implementation of advanced technologies like Vision AI, and fostering a safety-first culture. Such measures safeguard not only employees but also mining operations’ financial and reputational health.

Vision AI’s Role in Mining Safety

In the high-stakes mining environment, where every decision can have significant safety implications, Vision AI emerges as a critical ally. With a suite of safety applications meticulously designed for the mining industry, Vision AI is improving how safety is perceived and implemented.

Vision AI provides a comprehensive array of specialized applications, encompassing but not limited to the following:

- Restricted Zone Monitoring: Enforces secure areas automatically, alerting on breaches.

- Hazard Zones: Designates and oversees areas of elevated risk to reinforce safety protocols.

- Atmosphere Monitoring: Monitors air conditions, issuing alerts for hazardous gas levels or insufficient oxygen.

- Dwell Time: Regulates the time span workers spend in danger zones to maintain safety compliance.

- Minimum Workers: Guarantees a safe minimum number of staff in essential operational zones.

- Maximum Workers: Controls the crowd in work areas to avoid accidents due to overstaffing.

- Vehicle Monitoring: Tracks vehicle activity to mitigate collision risks and streamline traffic.

- PPE Compliance: Ensures consistent use of necessary safety equipment to protect workers from injury.

Operational Mechanics of Vision AI

Vision AI everages video feeds and sensor data, processing this information with advanced machine learning algorithms capable of identifying potential hazards and ensuring adherence to safety regulations. This technology continuously learns from the operational patterns within the mine, tailoring its monitoring and alerting mechanisms to fit the site’s specific needs. It proactively sends warnings to key personnel when it detects safety protocol violations or immediate threats, allowing for prompt and preventive measures. Vision AI empowers mining companies to move beyond reactive safety approaches by forecasting and neutralizing dangers, fostering a proactive safety culture.

Deep Dive into the Safety Applications

1. Restricted Zone Monitoring

Overview and Advantages:

Visionify’s Restricted Zone Monitoring is engineered to enhance the security of mining operations. This system utilizes cutting-edge AI to set up virtual boundaries around hazardous or restricted areas within a mining site. When these boundaries are crossed, it quickly notifies the supervisory team, enabling swift action to potential safety breaches. Its advantages include:

- Accident Deterrence: Actively alerts to unauthorized access, mitigating the risk of accidents.

- Operational Integrity: Ensures that high-security zones are maintained, upholding strict operational practices.

- Security Reinforcement: Acts as a safeguard against intrusions, protecting staff and critical infrastructure.

Application in the Mining Industry:

Restricted Zone Monitoring becomes essential for managing access to critical areas, such as demolition sites, machinery operational pathways, or toxic material storage locations in mining. It continuously observes these zones and triggers alarms if a breach occurs. For instance, should a miner mistakenly move into a scheduled blast area, the system can initiate an urgent alert, facilitating rapid evacuation and maintaining operational continuity. Applying this real-time monitoring system is crucial for upholding high safety standards amidst the complexities of mining operations.

2. Hazard Zones

The Hazard Zones app is adept at pinpointing and labeling high-risk areas in mining environments. This tool leverages advanced AI to highlight zones susceptible to specific dangers, such as areas with frequent heavy equipment use or unstable ground. It serves as a critical mechanism for alerting workers and management about these risks, significantly improving the safety measures in place.

Usage in the Mining Sector

In mining, where safety risks are a constant concern, the Hazard Zones application becomes an integral part of the safety strategy. It identifies explicitly and monitors areas needing heightened safety awareness. For example, in sections of a mine where there’s heavy machinery movement or overhead crane activity, the app can alert workers entering these zones or flag any breach of safety practices. This level of real-time monitoring and alerting protects the workforce from immediate dangers and cultivates a proactive approach to risk management, which is vital for the safety culture in mining operations.

3. Atmosphere Monitoring

Critical Role in Confined Spaces

Air quality is a paramount concern in mining, particularly in underground and confined areas. Vision AI’s Atmosphere Monitoring application is tailored to monitor these spaces with a high risk of harmful gas exposure and oxygen deficiency. This tool is vital for detecting dangerous atmospheric changes, a common issue in mining due to the nature of operations and the geographical characteristics of mining sites.

Functionality of Real-time Alerts

Equipped with real-time detection features, the Atmosphere Monitoring application continuously assesses air quality, focusing on gas concentrations and oxygen levels. When it detects unsafe atmospheric conditions, it swiftly issues alerts. This immediate response mechanism is critical in the mining environment, facilitating timely evacuation or other necessary safety actions in response to air quality threats. By providing instant notifications and updates, the tool plays a crucial role in maintaining ongoing safety management, which is essential in mining operations’ dynamic and potentially hazardous atmosphere.

4. Dwell Time Monitoring

Dwell Time Monitoring is an essential feature of Vision AI’s safety applications, specifically geared toward monitoring workers’ duration in hazardous areas of a mine. It plays a key role in enforcing safety regulations, ensuring employees do not stay beyond safe time limits in high-risk zones. These limits are carefully set based on risk assessments and compliance standards, making Dwell Time Monitoring a critical tool for adhering to safety protocols.

Enhancing Safety and Efficiency in Operations

Dwell Time Monitoring significantly bolsters both safety and operational efficiency in mining. Controlling workers’ exposure to potentially dangerous conditions effectively reduces the likelihood of accidents and health issues related to extended exposure to high-risk environments. This proactive approach to safety protects the workforce and contributes to smoother operational flow. With enforced time limits, mining activities in hazardous zones are performed more efficiently and within compliance, ensuring uninterrupted and productive mining operations. This application thus balances the critical aspects of safety and efficiency, ensuring a safer and more effective mining environment.

5. Minimum and Maximum Workers Monitoring

Optimizing Staffing in Sensitive Zones

Visionify’s Min and Max Workers Monitoring application is vital to managing staff levels in critical mining areas. It ensures sensitive zones are neither understaffed nor overcrowded, maintaining a balance crucial for safety and efficiency. The Min Workers feature verifies that essential tasks, such as operating heavy machinery, have sufficient personnel. At the same time, the Max Workers function prevents the risks associated with overcrowding, particularly in confined spaces.

Compliance and Safety Management

This monitoring tool is vital for adhering to safety standards and operational policies. It provides real-time workforce data, enabling quick adjustments to maintain prescribed staff levels. By ensuring these parameters are consistently met, the application enhances safety and prevents operational disruptions, making it an essential component of a well-regulated mining operation.

6. PPE Compliance Monitoring

In mining, Vision AI-powered PPE Compliance Monitoring plays a crucial role by using AI to ensure that workers adhere to essential safety gear protocols. It employs image recognition to continuously check for proper use of personal protective equipment, such as helmets, gloves, and safety glasses, swiftly identifying and addressing non-compliance.

This application is vital for miners’ safety, as it ensures that everyone is adequately equipped to handle the hazards of their environment. The system greatly diminishes the likelihood of workplace injuries by actively monitoring and prompting immediate action on PPE lapses. Its consistent oversight reinforces a safety-first culture, making PPE a fundamental part of daily operations and elevating the overall safety standards in mining activities.

7. Enhancing Vehicle Navigation with Monitoring

Visionify’s Vehicle Monitoring apps are crucial in enhancing safety in mining environments. It focuses on creating safe vehicle pathways and managing traffic effectively. The system uses AI to interpret real-time visual data, which is crucial for planning secure routes and traffic flow in mines. This includes identifying potential risks, coordinating vehicle movements, and averting accidents in busy mining areas.

A key aspect of Vehicle Monitoring is its reliance on real-time data to refine vehicle navigation strategies continuously. The system creates detailed heat maps and provides insights that adjust to the dynamic conditions of a mine. It monitors vehicle movements and anticipates traffic trends, which is crucial for reducing risks associated with vehicular activities in mines. These real-time updates and alerts facilitate a more responsive and safe approach to vehicle management. In the complex terrain of mining sites, this proactive vehicle navigation management significantly enhances safety and operational efficiency.

Conclusion

Vision AI: A Game-Changer in Mining Safety

Vision AI has revolutionized mining safety, introducing AI-driven tools that enhance mine operations. This suite of applications has transformed the mining environment, making it safer, more aware, and responsive.

Elevating Industry Safety Standards

Committed to advancing safety, Vision AI continuously evolves its technologies to meet and exceed industry standards. By leveraging AI and machine learning, Vision AI ensures compliance with current safety regulations and prepares for future industry challenges.

Future Prospects of AI in Mining Safety

Looking forward, the role of AI in mining safety is poised for further growth. We expect deeper integration with emerging technologies for more advanced safety solutions, like comprehensive IoT monitoring and predictive analytics. These advancements will create a mining sector where safety is an integral part of operations, continually adapting and advancing. Vision AI is at the forefront of this safety evolution, shaping a safer and more efficient mining future.