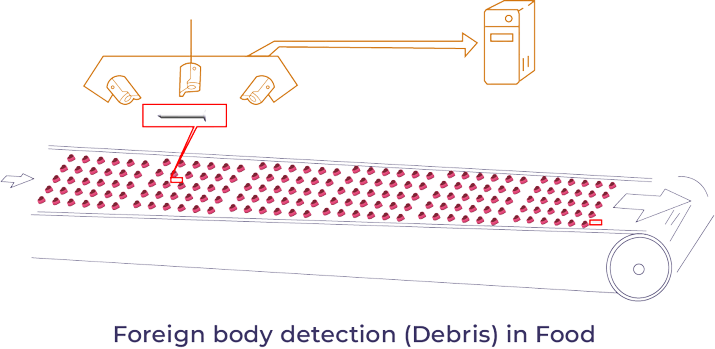

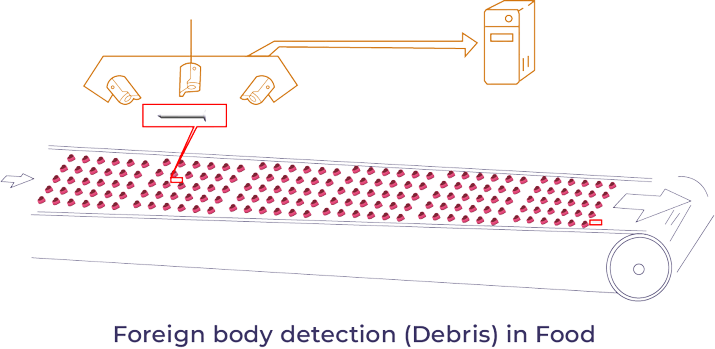

Foreign Body/Debris Detection in Food

AI-powered foreign objects detection in food using computer vision. Our solution detects different types of foreign bodies in food products (plastic pieces, metal pieces, cardboard pieces etc).

With Visionify’s factory vision solution you get a competitive advantage & improve your bottom line. Contact us today to see how Visionify can help you monitor in real-time and make smarter decisions on products you manufacture.

Visionify team helped build pilot solutions and models for us using both visible and IR cameras. The pilot process was quick and insights this system is generating is invaluable. We are quickly expanding this solution to the rest of the organization.

Dustin Dickinson

Pilgrim's Inc

Our solution is ideal for packed, unpacked and frozen food products.

If foreign material contamination is present in your products, it will be detected, identified, and segregated in seconds.

We designed this solution for max belt speeds to deploy in any manufacturing unit.

Our solution is cost-effective and has several attributes that make it superior to competition. It will help you increase productivity and enhance customer satisfaction and loyalty.

Mix and match products with minimal programming. Great for on-off manufacturing runs.

We make your production process faster, easier and more streamlined.

With Visionify’s factory vision solution you get a competitive advantage & improve your bottom line. Contact us today to see how Visionify can help you monitor in real-time and make smarter decisions on products you manufacture.

No posts found!

Copyright © 2022 – 2023 Visionify.ai