Product labels create a product’s first impression. This is where consumers determine the look, feel, and taste of a product. Food and beverage labels usually contain origin, date and expiry, amount or volume, and class. To leverage product-specific data to improve supply chain management and prevent food fraud at points of sale, these labels must be recognized automatically.

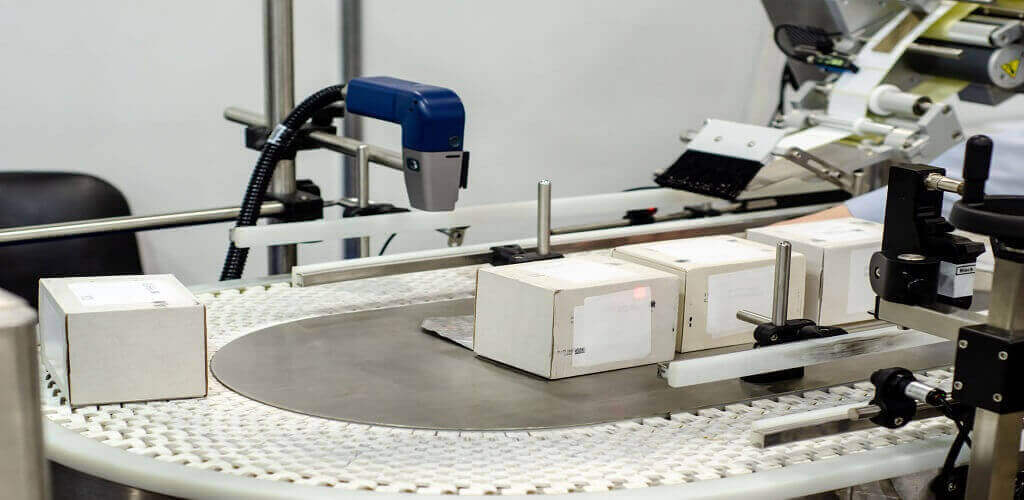

Machine Vision systems have many advantages over the label placement and inspection methods. Machines can place labels equally or faster than people. Human operators find it very difficult to inspect labels as carefully as a machine vision solution can.

Many defects such as gaps between label and edge of a container are visible features that a machine can detect easily. Other defects like embedded particles or wrinkles are usually invisible to the human eye. Still, they can be detected by measuring geometric parameters, scanning with special lighting, or using different wavelengths of light (color camera).

Challenges

1. Poor ink quality and low-contrast printing make it difficult to read barcodes and check labels

2. Barcode errors and poor label quality can slow production, making it harder for vendors and partners to keep up with demand.

3. During the labeling process, it’s hard to find defects on curved surfaces and items at an angle.

Solution

Quality inspections help ensure labeling is free of defects. AI-based label checking uses algorithms to detect torn, wrinkled and wrapped labels’ errors and defects. To inspect labels this solution looks for flaws in color, varying size or shape of labels, and that they are of promised quality. It also makes sure your labels are perfect before you ship your products.