Navigating PPE Compliance in Challenging Safety Environments

See It In Action

Safety AI Software in Action

See how Visionify's Safety AI Software monitors workplace safety in real-time

Example Videos

Safety AI Software in Action

See how Visionify's Safety AI Software monitors workplace safety in real-time

Forklift Zone Monitoring with Vision AI

See how Vision AI monitors forklift zones in real-time to prevent accidents

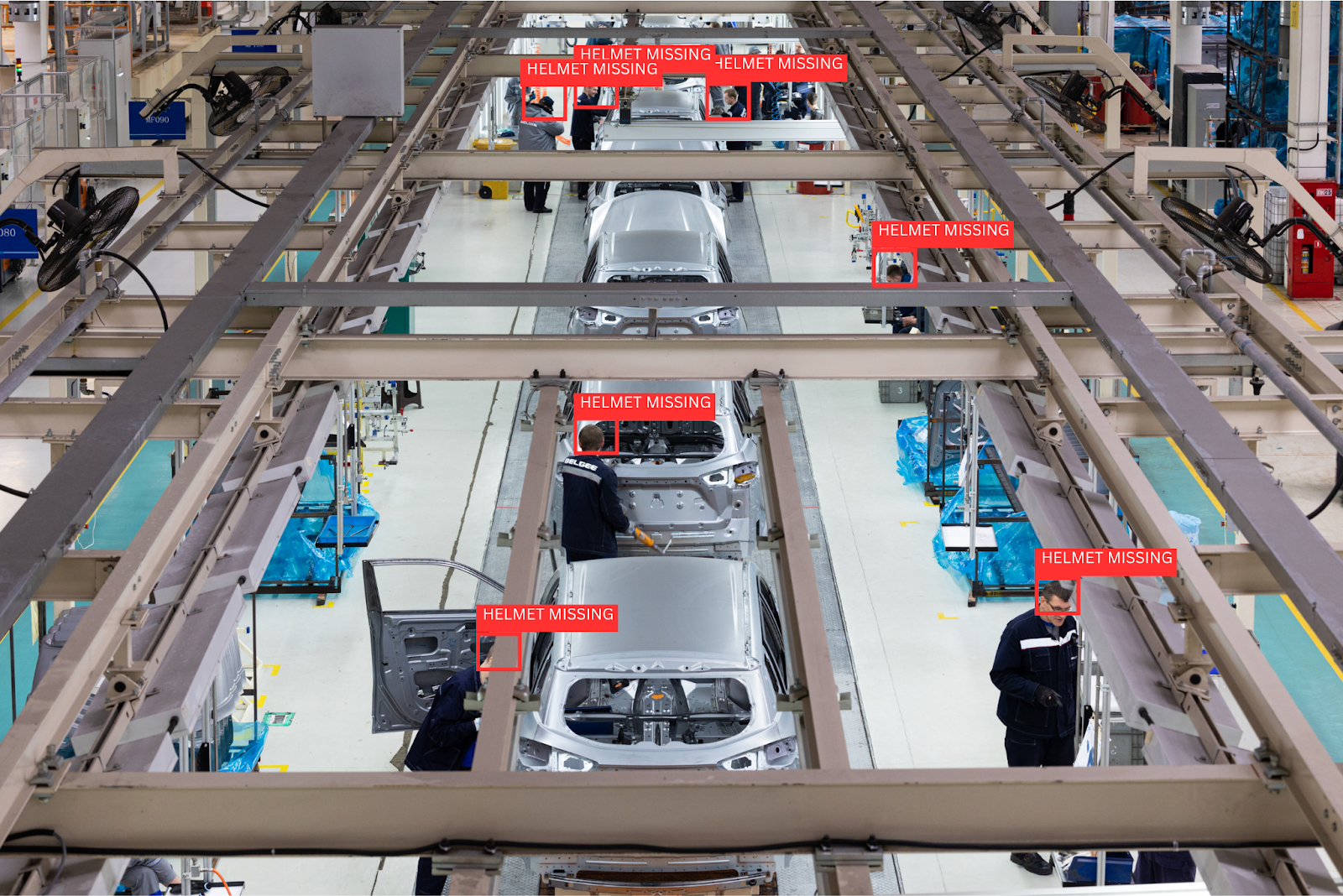

Hard Hat Compliance in Manufacturing

Vision AI PPE Compliance for Manufacturing

Key Takeaways

- Evolving Challenges: Traditional safety monitoring struggles to keep pace with modern industrial environments

- Proactive Solution: Vision AI provides real-time PPE compliance monitoring across diverse industries

- Significant Impact: Proper PPE compliance can prevent up to 37% of workplace accidents

- Industry Adaptability: Vision AI systems can be customized for manufacturing, construction, and warehousing needs

- Beyond Monitoring: Vision AI offers analytics that improve overall safety strategies

The Evolving Landscape of Workplace Safety

In today's rapidly changing industrial environments, workplace safety faces unprecedented challenges. Traditional safety approaches—relying heavily on manual monitoring and reactive measures—are increasingly inadequate for the complex, fast-paced operations of modern manufacturing plants, construction sites, and warehouses.

These conventional methods often suffer from inconsistent application, human oversight limitations, and delayed response to safety violations. As industries evolve with new technologies and processes, so too must their safety protocols adapt to address emerging risks and maintain regulatory compliance.

Modern industrial environments require advanced safety monitoring solutions

Modern industrial environments require advanced safety monitoring solutions

Understanding Vision AI: The Foundation of Modern Safety Monitoring

Vision AI represents a revolutionary approach to workplace safety monitoring. This technology combines artificial intelligence with computer vision to analyze visual data from cameras positioned throughout work environments. The system processes this information in real-time, identifying safety compliance issues and potential hazards as they occur.

How Vision AI Works

The technology operates through two critical processes:

-

Training: Vision AI systems learn through exposure to thousands of images showing both proper and improper PPE usage across various scenarios. This comprehensive training enables the AI to recognize different types of safety equipment and their correct application.

-

Object Detection: Once deployed, the system continuously analyzes video feeds, identifying objects like helmets, gloves, and safety vests. It can distinguish between compliant and non-compliant situations, even in challenging conditions with variable lighting or partially obscured views.

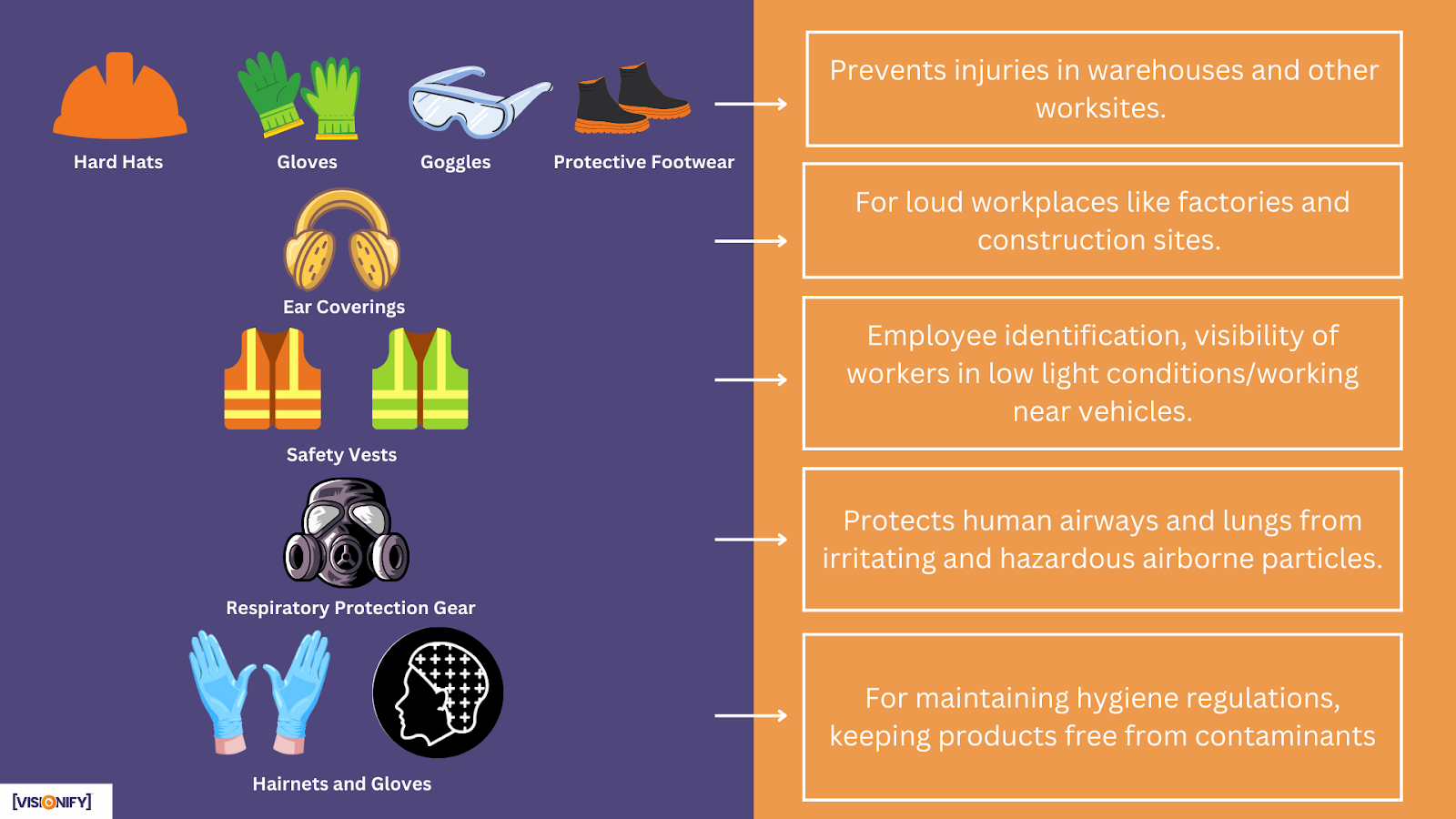

PPE Compliance: A Critical Safety Component

Personal Protective Equipment (PPE) serves as the last line of defense against workplace hazards. According to the Occupational Safety and Health Administration (OSHA), proper PPE compliance can prevent approximately 37% of workplace accidents—translating to potentially preventing 126 million injuries and saving almost a million lives globally each year.

Despite this critical importance, ensuring consistent PPE usage remains challenging across industries:

- Manufacturing: Workers face risks from machinery, chemicals, and noise exposure, requiring specialized PPE that may vary between different production areas

- Construction: Dynamic environments with constantly changing hazards demand different types of PPE as workers move between tasks and locations

- Warehousing: High-traffic areas with forklifts and heavy materials create unique safety challenges requiring specific visibility and protection equipment

Vision AI Applications Across Industries

Vision AI adapts to the unique safety requirements of different industrial environments:

Manufacturing Plants

In manufacturing settings, Vision AI monitors for specific PPE requirements that may vary between production lines. For example, when a worker operates heavy machinery without wearing required safety gloves, the system immediately detects this violation and alerts supervisors, preventing potential hand injuries.

Construction Sites

Construction environments present constantly changing hazards. Vision AI systems monitor for hard hat usage in areas with overhead risks, fall protection harnesses at heights, and appropriate footwear on uneven surfaces. The technology can adjust its monitoring parameters as construction progresses and different safety requirements emerge.

Warehouse Operations

In fast-paced warehouse environments, Vision AI ensures workers wear high-visibility vests in forklift areas and appropriate back support when lifting heavy items. The system can monitor specific zones differently, applying relevant PPE requirements based on the activities and risks in each area.

Vision AI systems can detect multiple types of PPE across different industrial environments

Vision AI systems can detect multiple types of PPE across different industrial environments

The Vision AI Advantage

Vision AI offers several critical advantages over traditional safety monitoring approaches:

Continuous Real-Time Monitoring

Unlike periodic safety inspections, Vision AI provides uninterrupted monitoring throughout all operational hours. This constant vigilance ensures no safety violations go unnoticed, regardless of when they occur or which supervisor is on duty.

Automated Alerts for Immediate Response

When the system detects PPE non-compliance, it instantly generates alerts to safety personnel. This immediate notification allows for rapid intervention before an accident occurs, rather than discovering compliance issues during post-incident investigations.

Pattern Analysis for Proactive Safety Improvements

Beyond individual violations, Vision AI analyzes compliance patterns over time. The system can identify:

- Specific areas with frequent violations

- Times of day when compliance decreases

- Types of PPE most commonly neglected

These insights enable targeted safety training, environmental modifications, or workflow adjustments to address root causes of non-compliance.

Customizable Monitoring Parameters

Vision AI can be configured to monitor different zones according to their specific safety requirements. For example, the system might check for hearing protection near noisy equipment while monitoring for chemical-resistant gloves in areas where hazardous materials are handled.

Vision AI monitoring PPE compliance in a manufacturing environment

Vision AI monitoring PPE compliance in a manufacturing environment

Implementation Considerations

Implementing Vision AI for PPE compliance monitoring is remarkably straightforward in most industrial environments. The technology can often utilize existing security camera infrastructure, requiring minimal additional hardware installation. Cloud-based processing options eliminate the need for extensive on-site computing resources, while edge computing solutions are available for facilities with connectivity limitations.

Most organizations can deploy Vision AI safety systems with minimal disruption to existing operations, typically achieving full implementation within 2-4 weeks. The technology is scalable from small facilities to massive industrial complexes, with costs that align with the size and complexity of the operation.

Conclusion: The Future of Workplace Safety

As workplace environments continue to evolve, Vision AI represents a critical advancement in safety technology. By providing continuous, objective monitoring of PPE compliance, these systems address the limitations of traditional safety approaches while delivering actionable insights that drive ongoing improvements.

The statistics are compelling: with proper PPE compliance potentially preventing 37% of workplace accidents, Vision AI's ability to ensure consistent usage represents a significant opportunity to protect workers and reduce operational risks.

For organizations committed to creating safer workplaces while improving efficiency and compliance, Vision AI offers a powerful solution that adapts to the unique challenges of different industrial environments. As this technology continues to evolve, it promises to further transform how we approach workplace safety—moving from reactive responses to proactive prevention.

Ready to transform safety compliance in your workplace? Contact Visionify today to learn how our Vision AI solutions can enhance PPE compliance and create a safer work environment.

Frequently Asked Questions

Find answers to common questions about this topic

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Related Articles

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.