AI-Powered Safety: A New Era of Accident Prevention

See It In Action

Safety AI Software in Action

See how Visionify's Safety AI Software monitors workplace safety in real-time

Example Videos

Safety AI Software in Action

See how Visionify's Safety AI Software monitors workplace safety in real-time

Forklift Zone Monitoring with Vision AI

See how Vision AI monitors forklift zones in real-time to prevent accidents

Hard Hat Compliance in Manufacturing

Vision AI PPE Compliance for Manufacturing

Detect Smoke and Fire events with AI

How AI detects smoke and fire events in real-time

Slip and Fall Detection with AI

Real-time detection of slip and fall incidents

If a camera could save a life, would you look at safety differently?

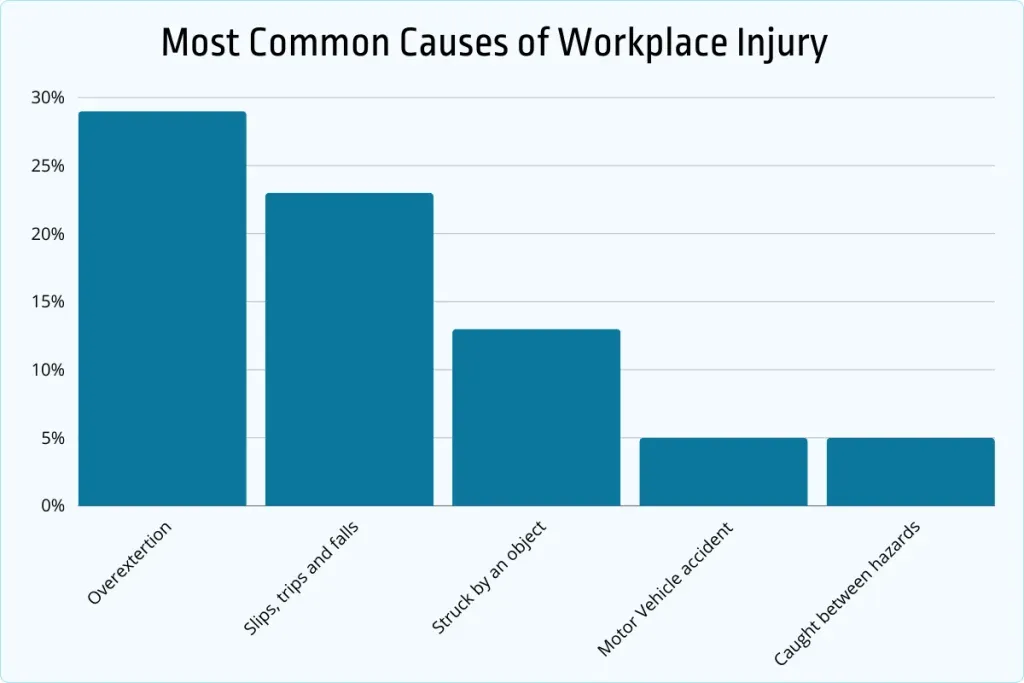

Every year, millions of people get injured at work—often because someone missed a small detail. A missing helmet. A wet floor. A forklift turning the wrong way. Most of these incidents are preventable, but human eyes can't be everywhere all the time. That's where AI is quietly changing the game.

The everyday reality of workplace accidents and safety challenges

The everyday reality of workplace accidents and safety challenges

Key Takeaways

- Real-Time Prevention: AI-powered systems detect hazards instantly, enabling intervention before accidents occur

- Proven Results: 40-60% reduction in safety incidents within 6 months of implementation

- Cost Savings: ROI typically achieved within 12-18 months through reduced incidents and insurance premiums

- 24/7 Monitoring: Continuous surveillance without human fatigue or attention lapses

- Predictive Analytics: Machine learning identifies patterns to predict and prevent future incidents

The Staggering Cost of Workplace Accidents

The financial and human cost of workplace accidents is enormous:

- $167 billion – Total annual cost of work-related injuries in the U.S. (National Safety Council, 2022)

- $40,000 – Average cost per medically consulted workplace injury

- $1.39 million – Average cost of a workplace fatality

- 885 fatal injuries – From falls, slips, and trips alone in 2023 (Bureau of Labor Statistics)

These aren't just numbers—they represent real people, families, and businesses. The good news? Most of these incidents are preventable with the right systems in place.

The Limitations of Traditional Safety Monitoring

Traditional safety monitoring has fundamental limitations that create gaps in protection:

- Human attention span – Security guards can effectively monitor only 20 minutes before attention wanes

- 24/7 coverage gaps – Shift changes and breaks create blind spots

- Reactive approach – CCTV footage is typically reviewed only after incidents occur

- Incomplete data – Manual reporting misses up to 50% of near-misses and minor violations

- PPE violations go unnoticed – Studies show that manual monitoring catches less than 30% of violations

The truth is, we can't fix what we don't see. Most safety systems are designed to react—not predict.

How AI-Powered Safety Works

AI-powered safety systems use computer vision to transform existing cameras into intelligent monitoring tools that understand what they see in real-time.

Real-Time Detection Capabilities

AI systems continuously analyze video feeds to detect:

- PPE violations – Missing hard hats, safety vests, gloves, or safety glasses

- Forklift safety risks – Speed violations, near-miss detection, restricted zone breaches

- Environmental hazards – Spills, leaks, smoke, and fire

- Behavioral safety issues – Mobile phone usage, unsafe work practices

- Area control violations – Unauthorized access, occupancy limits

When a potential hazard is detected, instant alerts are sent to supervisors and workers, enabling immediate intervention.

The Science Behind Computer Vision Safety

Computer vision AI works through four key processes:

- Object Detection – Identifying people, vehicles, equipment, and hazards in real-time

- Behavioral Analysis – Understanding movement patterns, speeds, and trajectories

- Pattern Recognition – Learning from historical data to predict potential incidents

- Anomaly Detection – Flagging unusual situations that deviate from normal operations

This technology processes thousands of frames per second, detecting violations that human eyes would miss in a fraction of a second.

Visionify's AI-powered safety monitoring platformTechnical Implementation

Seamless Integration

Visionify transforms your existing infrastructure into an intelligent safety system:

- Connects to existing CCTV cameras (no new hardware needed)

- Works with IP cameras, analog systems, and cloud-based video feeds

- Supports multiple camera brands and protocols

- Implementation typically takes 2-4 weeks

Edge Computing Architecture

- AI models run on-site at the edge—processing happens locally

- Real-time analysis with sub-second response times

- No dependency on internet connectivity for core functions

- Reduced bandwidth requirements compared to cloud-only solutions

Instant Alert System

- Multi-channel notifications: dashboard, email, SMS, Microsoft Teams, WhatsApp

- Configurable alert thresholds and escalation rules

- Location-specific alerts with camera and timestamp information

- Mobile app access for on-the-go monitoring

Privacy and Security

- On-premises deployment option for maximum data control

- Automatic face blurring to protect worker privacy

- SOC 2 Type II and GDPR compliant

- Encrypted data transmission and storage

Measurable Results

Organizations implementing AI-powered safety systems see consistent improvements across multiple metrics:

Safety Performance

- 40-60% reduction in safety incidents within the first 6 months

- 70% reduction in manual safety audits and inspections

- Faster incident response – Average response time reduced from 15 minutes to under 2 minutes

- Zero fatalities reported at facilities using Visionify for over 12 months

Operational Efficiency

- 50-80% reduction in time spent on safety documentation

- Automated compliance reporting – Generating audit-ready reports in minutes instead of days

- Reduced administrative burden – Safety teams can focus on training and improvement instead of paperwork

Financial Impact

- 15-30% reduction in workers' compensation premiums

- ROI typically achieved within 12-18 months through reduced incident costs

- Lower insurance costs – Some customers report 20-25% premium reductions

- Reduced downtime – Fewer incidents mean less production interruption

Cultural Transformation

- Increased worker confidence – Employees feel safer knowing the system has their back

- Proactive safety culture – Shift from reactive to preventive mindset

- Data-driven decision making – Safety improvements based on actual patterns, not assumptions

Predictive Safety Analytics

Traditional safety is reactive; it tells you what went wrong. Predictive safety uses AI to tell you what might go wrong, and helps stop it first.

How Predictive Analytics Work

Over time, Visionify learns your workplace patterns through machine learning:

Spatial Intelligence:

- Identifies high-risk zones where violations occur most frequently

- Maps traffic patterns and identifies collision-prone areas

- Suggests optimal placement of safety equipment and signage

Temporal Patterns:

- Recognizes peak hours when incidents are more likely

- Identifies shift patterns that correlate with higher risk

- Predicts when additional safety resources might be needed

Behavioral Insights:

- Tracks which types of violations occur most often

- Identifies specific work processes that need improvement

- Correlates environmental factors (weather, lighting) with safety incidents

Risk Scoring:

- Assigns risk scores to different areas and activities

- Prioritizes alerts based on severity and likelihood

- Provides predictive analytics for safety planning

Real-World Success Story

A global manufacturing brand with operations across multiple continents installed Visionify in several of their high-risk manufacturing plants.

The Challenge

Before Visionify, they relied on:

- Manual safety inspections conducted weekly

- Security guards monitoring 40+ camera feeds

- Incident reports filled out after accidents occurred

- Quarterly safety audits that took weeks to complete

Despite these efforts, they were experiencing:

- 2-3 recordable injuries per month

- Rising workers' compensation costs

- Difficulty identifying root causes of incidents

- Safety team overwhelmed with paperwork

The Results (After 6 Months)

- 70% reduction in manual audits – Automated compliance tracking freed up 40+ hours per week

- Zero recordable injuries in the monitored areas

- $180,000 saved in reduced workers' compensation costs

- Worker confidence increased – Employee surveys showed 85% felt safer with the system

- Safety culture shift – From "compliance-focused" to "prevention-focused"

The success in the initial plants led to company-wide rollout across all 12 manufacturing facilities.

Visionify.ai transforming workplace safety through AI-powered monitoring

Visionify.ai transforming workplace safety through AI-powered monitoring

AI Augments, Not Replaces

There's a misconception that AI replaces people. It doesn't. It helps safety teams focus on what matters most—preventing harm.

What AI Does

- Continuous monitoring without fatigue

- Processing thousands of data points simultaneously

- Detecting patterns humans might miss

- Providing instant alerts and documentation

- Analyzing trends across time and locations

What Humans Do

- Making judgment calls in complex situations

- Building relationships and trust with workers

- Training and coaching teams

- Developing safety culture and policies

- Strategic safety planning and improvement

The New Role of Safety Teams

With Visionify, EHS teams can focus on high-value activities:

- Training and Education – Use AI-identified patterns to create targeted training programs

- Root Cause Analysis – Investigate incidents with comprehensive video evidence and data

- Process Improvement – Develop solutions based on actual violation patterns, not assumptions

- Worker Engagement – Build relationships and safety culture instead of chasing paperwork

- Strategic Planning – Use predictive analytics to plan safety initiatives proactively

Getting Started

You don't need to automate everything overnight. Start small and expand as you see results.

A Phased Approach

Phase 1: Pilot Program (Weeks 1-4)

- Select 1-2 high-risk areas or specific safety scenarios

- Deploy Visionify with 5-10 cameras

- Train your safety team on the platform

- Establish baseline metrics for comparison

Phase 2: Expansion (Months 2-3)

- Add more safety scenarios based on pilot results

- Expand to additional high-risk zones

- Integrate with existing safety management systems

- Refine alert thresholds and workflows

Phase 3: Full Deployment (Months 4-6)

- Roll out across all critical areas

- Enable all relevant safety scenarios

- Develop custom scenarios for your specific needs

- Establish ongoing monitoring and optimization processes

Common Starting Points

Most organizations begin with one of these high-impact scenarios:

- PPE Compliance – Quick wins with immediate visibility

- Forklift Safety – Addresses one of the highest-risk areas

- Restricted Zones – Prevents unauthorized access to hazardous areas

- Slip and Fall Detection – Catches incidents in real-time for faster response

Privacy and Compliance

Visionify is built with privacy and compliance at its core:

- On-Premises Deployment – All video processing can happen on your own servers

- Automatic Face Blurring – Masks faces in all processed footage

- Person Anonymization – Tracks safety behaviors without identifying individuals

- SOC 2 Type II & GDPR Compliant – Meets international security and privacy standards

- End-to-End Encryption – For data in transit and at rest

- Role-Based Access Controls – With audit logs for all system access

Your video data stays secure—always. We've built trust with Fortune 500 companies, government agencies, and organizations handling sensitive operations.

Conclusion

AI isn't here to replace your safety culture—it's here to strengthen it. It's like having an extra set of eyes that never blink, never get tired, and never look away.

Because at the end of the day, every alert caught early could be a life saved.

Frequently Asked Questions

Find answers to common questions about this topic

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Related Articles

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.