Vision AI in Mining: Enhancing Safety and Redefining Operational Standards

See It In Action

Safety AI Software in Action

See how Visionify's Safety AI Software monitors workplace safety in real-time

Example Videos

Safety AI Software in Action

See how Visionify's Safety AI Software monitors workplace safety in real-time

Hard Hat Compliance in Construction

See how Vision AI detects hard hat violations in real-time

Hard Hat Compliance in Manufacturing

Vision AI PPE Compliance for Manufacturing

Key Takeaways

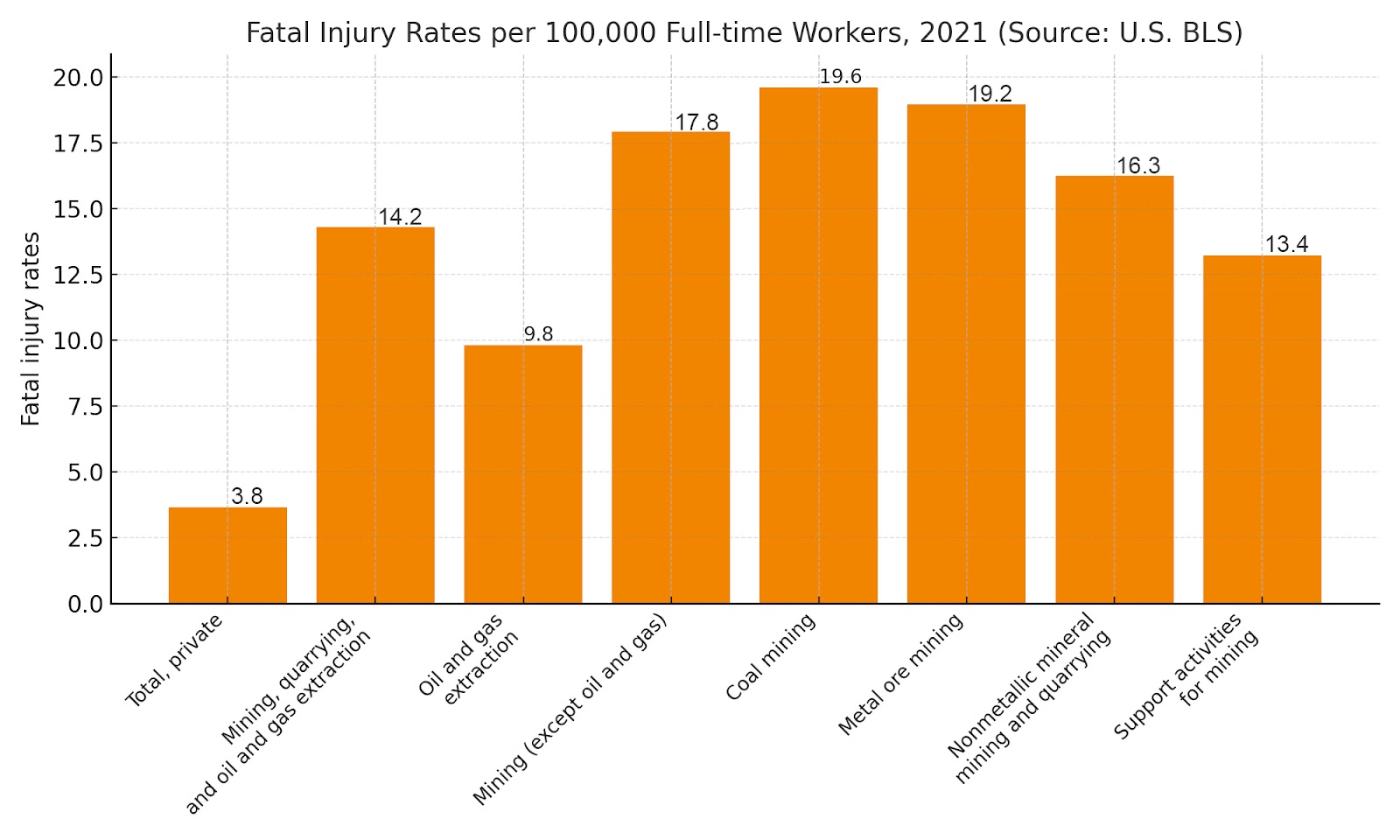

- High-Risk Industry: Mining has a fatality rate nearly four times higher than the private industry average

- Comprehensive Monitoring: Vision AI provides continuous surveillance of multiple safety factors simultaneously

- Proactive Protection: Real-time alerts enable intervention before incidents occur

- Specialized Applications: From restricted zone monitoring to PPE compliance, Vision AI addresses mining's unique challenges

- Proven Results: Early adopters report significant reductions in safety incidents and improved operational efficiency

The Safety Challenge in Mining Operations

Mining remains one of the world's most dangerous industries, with workers facing daily risks from heavy machinery, confined spaces, unstable ground, and hazardous atmospheres. The statistics tell a sobering story: according to the U.S. Bureau of Labor Statistics, the mining industry's fatal injury rate stands at 14.2 per 100,000 workers—nearly four times the private industry average of 3.8.

The human cost of mining accidents is immeasurable, while the economic impact is substantial. Safety incidents can lead to operational shutdowns, regulatory penalties, increased insurance premiums, and significant reputational damage. In an industry where margins are often tight, these consequences can threaten a company's viability.

Graph showing fatal injury rates for mining industry. Mining operations present numerous safety challenges that traditional monitoring methods struggle to address

Graph showing fatal injury rates for mining industry. Mining operations present numerous safety challenges that traditional monitoring methods struggle to address

Limitations of Traditional Safety Approaches

Conventional mining safety relies heavily on manual inspections, periodic air quality testing, and worker training. While these fundamentals remain important, they have inherent limitations:

- Manual inspections can't provide continuous monitoring

- Human observers may miss subtle warning signs

- Traditional gas detectors only monitor specific locations

- Paper-based compliance systems lack real-time enforcement

- Reactive approaches address incidents after they occur

These gaps in traditional safety protocols create opportunities for accidents to develop undetected, often with serious consequences.

Vision AI: Transforming Mining Safety

Vision AI represents a paradigm shift in mining safety management. By applying advanced computer vision and artificial intelligence to analyze visual data from cameras throughout mining operations, Vision AI creates a comprehensive safety monitoring system that never tires and can detect hazards at their earliest stages.

How Vision AI Works in Mining Environments

The system uses sophisticated algorithms to analyze video feeds in real-time, identifying safety concerns as they develop. When potential hazards are detected, the system immediately alerts safety personnel, allowing for prompt intervention before an incident occurs.

Vision AI systems provide continuous monitoring across mining operations, detecting hazards in real-time

Vision AI systems provide continuous monitoring across mining operations, detecting hazards in real-time

Key Vision AI Applications for Mining Safety

Restricted Zone Monitoring

Vision AI establishes virtual boundaries around dangerous areas, automatically detecting unauthorized entry and triggering immediate alerts. This prevents workers from inadvertently entering blast zones, areas with unstable ground, or locations with operating heavy machinery.

Hazard Zone Management

The system identifies and monitors high-risk areas, alerting workers who enter these zones to exercise additional caution. This creates an additional layer of protection in areas where specific dangers exist, such as overhead crane operations or locations with poor ground conditions.

Atmosphere Monitoring

In underground mining, air quality is a constant concern. Vision AI integrates with gas detection systems to monitor atmospheric conditions, providing early warning of dangerous gas levels or oxygen deficiency. The system can detect visual indicators of air quality issues and trigger evacuation alerts when necessary.

Dwell Time Monitoring

Vision AI tracks how long workers remain in hazardous areas, ensuring they don't exceed safe exposure limits. This is particularly important in zones with potential radiation, toxic substances, or extreme conditions where prolonged exposure increases risk.

Worker Count Management

The system ensures optimal staffing levels in critical areas. The Minimum Workers application verifies that sufficient personnel are present for safe operations, while the Maximum Workers function prevents overcrowding in confined spaces that could impede emergency evacuation.

Vehicle Monitoring

Vision AI tracks vehicle movements throughout mining operations, helping prevent collisions and ensuring vehicles remain on designated paths. The system can detect when vehicles enter unauthorized areas or when pedestrian workers are at risk from vehicle operations.

PPE Compliance

Perhaps the most widely implemented Vision AI application in mining is automated PPE detection. The system continuously monitors workers to ensure they're wearing required safety equipment such as helmets, safety glasses, high-visibility clothing, and respiratory protection.

Implementation and Integration

One of Vision AI's strengths is its adaptability to existing mining infrastructure:

- Flexible Deployment: The system can utilize existing security cameras or new purpose-specific installations

- Scalable Solution: Start with critical applications and expand as needed

- Integration Capabilities: Works alongside existing safety systems and sensors

- Cloud or Edge Computing: Options for both connected and remote mining operations

Most mining operations can implement Vision AI with minimal disruption to existing workflows, often seeing safety improvements within weeks of deployment.

Return on Investment

The business case for Vision AI in mining safety is compelling:

- Reduced accident rates and associated costs

- Decreased insurance premiums

- Improved regulatory compliance

- Enhanced operational efficiency

- Strengthened safety culture

Mining companies implementing Vision AI typically report accident reductions of 30-50% within the first year, with ROI achieved in as little as 6-12 months.

Conclusion

In an industry where safety challenges are as deep and complex as the mines themselves, Vision AI offers a powerful new approach to protecting workers and operations. By providing continuous monitoring, instant alerts, and data-driven insights, Vision AI addresses the limitations of traditional safety methods and creates a proactive safety culture.

For mining companies committed to sending every worker home safely while improving operational efficiency, Vision AI represents not just an innovative technology but an essential investment in their most valuable asset—their people.

Ready to transform safety in your mining operations? Contact Visionify today to learn how our Vision AI solutions can protect your workers and improve your safety outcomes.

Frequently Asked Questions

Find answers to common questions about this topic

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Related Articles

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.