Reducing Occupational Risks with AI-powered Time Limited Area Monitoring

See It In Action

Time Limited Area Monitoring in Action

See how AI tracks worker exposure time in hazardous zones

Example Videos

Time Limited Area Monitoring in Action

See how AI tracks worker exposure time in hazardous zones

Key Takeaways

- Exposure Management: AI tracks worker time in hazardous zones to prevent overexposure

- Real-Time Alerts: Instant notifications when safety time thresholds are exceeded

- Cross-Industry Application: Effective in manufacturing, mining, construction, and more

- Compliance Automation: Simplifies adherence to regulatory exposure limits

- Data-Driven Safety: Analytics identify patterns to improve safety protocols

The Critical Challenge of Time-Based Exposure

In high-risk industrial environments, the duration of exposure often determines the level of danger workers face. From extreme temperatures to toxic atmospheres, many workplace hazards become increasingly dangerous with prolonged exposure. Traditional safety measures frequently fail to address this time-sensitive aspect of risk management.

Time Limited Area Monitoring represents a significant advancement in workplace safety technology by specifically targeting this challenge. Using AI-powered computer vision, these systems track precisely how long workers remain in designated hazardous zones, ensuring they don't exceed safe exposure thresholds.

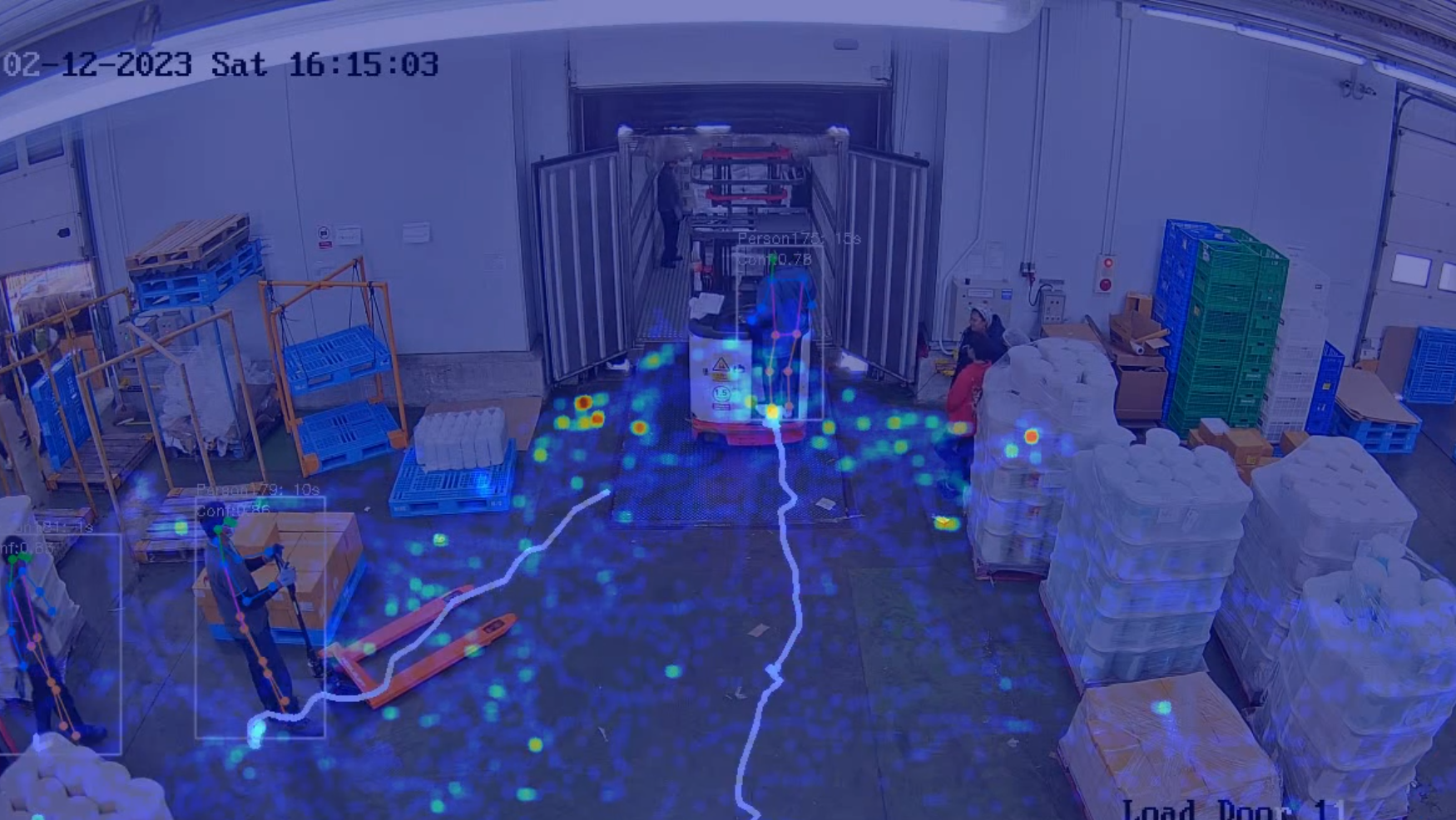

AI system tracking worker's time spent in a restricted zone

AI system tracking worker's time spent in a restricted zone

How Time Limited Area Monitoring Works

The system operates through a straightforward but powerful process:

- Zone Definition: Safety managers designate specific areas as time-limited zones

- Time Threshold Setting: Maximum safe exposure times are established for each zone

- Continuous Monitoring: AI-powered cameras track personnel entering and remaining in zones

- Real-Time Tracking: System calculates cumulative exposure time for each worker

- Automated Alerts: Notifications trigger when time limits approach or exceed thresholds

This proactive approach prevents safety incidents before they occur by ensuring workers rotate out of hazardous environments before reaching dangerous exposure levels.

Critical Applications Across Industries

Manufacturing Environments

In manufacturing facilities, Time Limited Area Monitoring proves invaluable for:

- Areas with extreme heat exposure near furnaces or smelting operations

- Zones with high noise levels requiring limited exposure

- Spaces with potential chemical or particulate exposure

- Confined spaces with atmospheric or ergonomic concerns

By enforcing rotation schedules automatically, the system prevents both acute injuries and long-term health effects from cumulative exposure.

Mining Operations

Mining presents unique challenges where time-limited monitoring significantly enhances safety:

- Underground areas with poor ventilation

- Zones with potential toxic gas accumulation

- High-vibration environments near drilling operations

- Areas with radiation or other invisible hazards

The system ensures miners don't exceed safe working periods in these high-risk environments, reducing both immediate dangers and long-term health impacts.

Time Limited Area Monitoring in a mining environment

Time Limited Area Monitoring in a mining environment

Construction Sites

On dynamic construction sites, the system monitors:

- Unstable structures during critical construction phases

- Areas with fall hazards requiring heightened attention

- Zones with active heavy machinery operation

- Spaces with temporary hazardous conditions

By preventing fatigue-related accidents and ensuring proper rotation, the technology addresses one of the construction industry's most persistent safety challenges.

Chemical Processing

In chemical facilities, the system provides crucial protection by monitoring:

- Areas with potential toxic substance exposure

- Zones requiring specific respiratory equipment with limited use times

- Spaces with extreme temperature conditions

- Environments with explosion or reaction risks

The precise tracking ensures workers never exceed safe exposure limits, preventing both immediate dangers and long-term health effects.

Key Benefits Beyond Basic Safety

Regulatory Compliance Automation

Time Limited Area Monitoring simplifies compliance with various regulations:

- OSHA standards for hazardous environment exposure

- Industry-specific time-limited exposure requirements

- Documentation of safety protocol adherence

- Evidence of due diligence for liability protection

The system automatically generates comprehensive records, streamlining reporting and audit processes.

Operational Efficiency Improvements

Beyond safety, the technology enhances operational performance through:

- Optimized worker rotation schedules

- Reduced downtime from safety incidents

- Decreased absenteeism from exposure-related illness

- More efficient resource allocation

These efficiency gains often offset implementation costs while simultaneously improving safety outcomes.

Data-Driven Safety Enhancement

The analytics provided by Time Limited Area Monitoring enable continuous improvement:

- Identification of high-risk zones requiring additional controls

- Recognition of patterns in exposure time violations

- Insights into workflow optimization opportunities

- Quantifiable metrics for safety program effectiveness

This data-driven approach transforms safety from a reactive necessity to a proactive advantage.

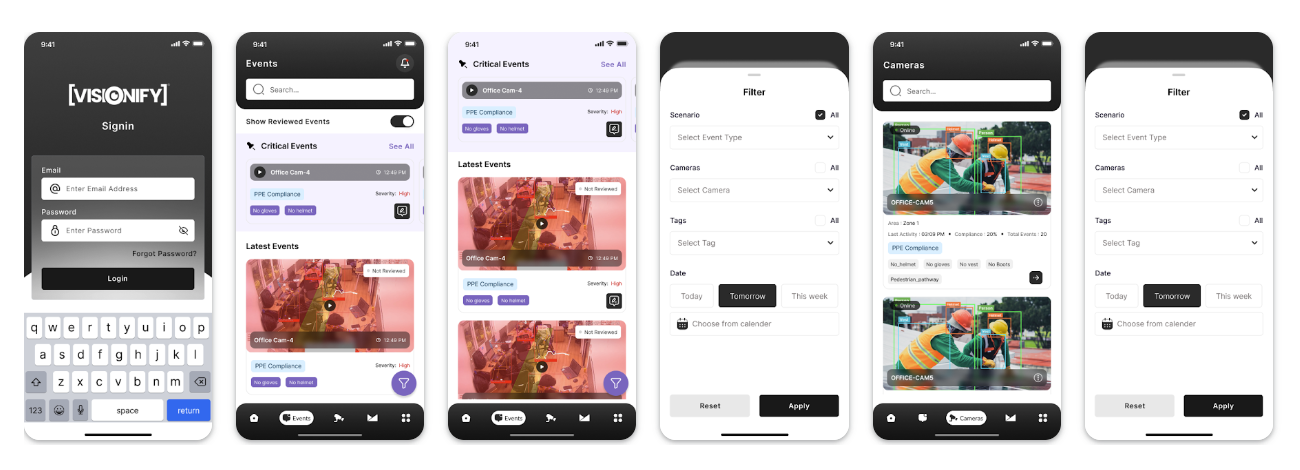

Implementation: Straightforward Integration

Visionify's Time Limited Area Monitoring system is designed for seamless adoption:

- Works with existing CCTV infrastructure

- Requires minimal additional hardware

- Integrates with current safety management systems

- Scales from single zones to enterprise-wide deployment

The web-based management dashboard provides intuitive controls for zone definition, time threshold settings, and alert configuration, making the system accessible to safety teams without extensive technical expertise.

Visionify's Mobile Application for EHS Management

Visionify's Mobile Application for EHS Management

Conclusion: Transforming Time-Based Safety Management

Time Limited Area Monitoring represents a significant advancement in workplace safety technology by addressing the critical but often overlooked factor of exposure duration. By providing automated, real-time enforcement of time-based safety protocols, these systems fill a crucial gap in traditional safety approaches.

For organizations serious about protecting their workforce from time-sensitive hazards, AI-powered monitoring offers an effective, efficient solution that enhances safety outcomes while simplifying compliance and improving operational efficiency.

As workplace safety standards continue to evolve, Time Limited Area Monitoring provides the proactive, data-driven approach needed to stay ahead of emerging challenges and create truly safe working environments.

Ready to enhance your workplace safety with AI-powered Time Limited Area Monitoring? Contact Visionify today to schedule a demonstration and discover how our solutions can protect your workforce from time-sensitive hazards.

Frequently Asked Questions

Find answers to common questions about this topic

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Related Articles

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.