Do you know a research team has taught software how to detect unsafe foods with the help of algorithms? With a 74 percent accuracy rate, this software predicted food product recalls using reviews. This is an output of innovative AI solutions for food inspection. According to World Bank, foodborne Illnesses cost US $110 billion per year. This blog throws light on the opportunities that artificial intelligence has in redefining food inspection industry.

What is food inspection with AI?

The food business requires a comprehensive method for organizing, analyzing, integrating, and coming to a conclusion. That may be used to evaluate and monitor key performance indicators (KPIs) linked to food safety and hygiene.

Machine learning and Artificial Intelligence can transform food hygiene and safety data management by moving it away from a simultaneous and repeating control approach toward an effective monitoring and quality system.

AI may provide a feedback loop for present food safety and quality systems. If they are fulfilling the objectives and aspirations of business quality control management to create continuous analytical data that can be presented in reports to senior management.

Product recalls using reviews.

For FDA it takes months to detect a problem with a food product, confirm the problem, and issue a recall. BERT’s detection problem is more superficial (Bidirectional encoder representation from transformations).

The FDA team calls BERT, an artificial intelligence computer, trained to identify unsafe foods using statistics and algorithms. For example, BERT predicted food product recalls with a 74 percent accuracy rate using reviews with this training.

The team has looked at previous FDA reviews to find key phrases in unsafe food reviews. Key phrases like sick, rotten, and foul used for identification. Next the team went over reviews using those phrases.

BERT analyzed 20,000 reviews for bread, cheese, packaged goods and baby foods.

This research aims to fast-track this workflow which takes more time to report a food-related issue. However, we can detect such unsafe foods earlier. As a result the FDA can undertake an inspection and issue a recall soon that it affects fewer people.

Predicting decaying of the food in advance

According to a study, students integrated artificial intelligence in food safety agencies to help the food-beverage business and the hotel industry reduce losses due to food decay.

Using artificial intelligence to evaluate the current temperature of the food, this study can estimate when food will decay.

UN environment program says every year over one-third of the food produced for human use roughly 1.3 billion tonnes is wasted.

Adroit market research says that the global food safety testing market was valued at >USD 18 billion in 2019.

Students used data analytics to determine the temperature of multiple food products over three months. They gathered data by combining time-series sensors with deep learning models and machine learning to predict timeframe of changing food temperatures.

The model helps in monitoring gas, humidity levels, and temperature of vacuum-packed foods and sends an alert whenever the reserve food temperature increases. In addition this study aims to create an algorithm that can detect temperature swings within every food product. Predicts when particular food will go rotten based on previous records.

With this solution food businesses can save their food from being rotten and use it appropriately.

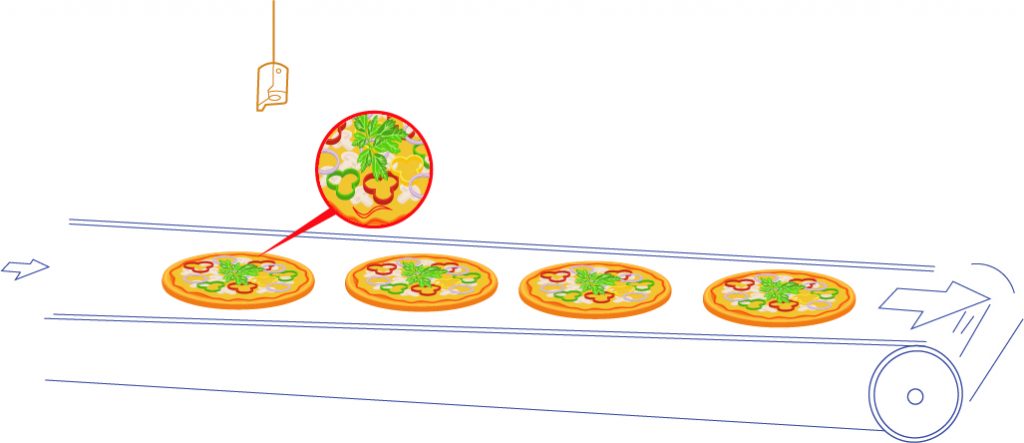

Visionify food debris detection

Visionify provides debris detection solutions for food manufacturing companies. This includes detecting debris on food manufacturing belts with infrared and IR cameras. So that debris can detected even at room temperature. In addition, the camera will have a PLC integration to trigger the reject belt which will move current items on the conveyor belt to the reject mechanism.

Conclusion

With advancements in technology food experts can benefit significantly from those new advances that artificial intelligence presents. It could redefine the food inspection industry by improving efficiency, processing time and providing helpful information about food quality. Consequently utilization of AI may have offered a pathway to overcoming issues in food inspection. It is a fact that AI can redefine food inspection industry. As we have experienced with self-driving cars AI trained to handle certain situations better than humans.

At Visionify we leverage computer vision ai solutions to solve real-world problems by efficiently processing images. We offer solutions for computer vision applications like packaging-related defect detection and correction, food debris detection in the food manufacturing process, and document parsing. Call us today to schedule a demo of our solutions!