Enhancing Workplace Safety with Station Occupancy Monitoring

See It In Action

Station Occupancy Monitoring in Action

See how AI tracks worker presence at critical stations

Example Videos

Station Occupancy Monitoring in Action

See how AI tracks worker presence at critical stations

Key Takeaways

- Real-Time Tracking: AI continuously monitors worker presence at critical stations

- Instant Alerts: Immediate notifications when stations are understaffed or overcrowded

- Cross-Industry Application: Effective in manufacturing, construction, mining, and more

- Dual Benefits: Enhances both safety compliance and operational efficiency

- Data-Driven Insights: Analytics optimize staffing and resource allocation

Understanding Station Occupancy Monitoring

In high-risk industrial environments, ensuring proper staffing at critical workstations is essential for both safety and operational efficiency. Station Occupancy Monitoring uses advanced AI and computer vision technology to continuously track worker presence, providing real-time visibility into whether stations are properly staffed, understaffed, or overcrowded.

This intelligent monitoring system transforms standard surveillance cameras into powerful safety tools that help prevent accidents, improve compliance, and optimize resource allocation across industrial operations.

AI system tracking worker presence at manufacturing stations

AI system tracking worker presence at manufacturing stations

How Station Occupancy Monitoring Works

Visionify's Station Occupancy Monitoring system operates through a streamlined process:

- Station Definition: Safety managers designate specific areas as monitored stations

- Occupancy Parameters: Minimum and maximum staffing requirements are established for each station

- Continuous Monitoring: AI-powered cameras track personnel presence at designated stations

- Real-Time Analysis: System determines if stations are properly staffed, understaffed, or overcrowded

- Automated Alerts: Notifications trigger when occupancy levels fall outside safe parameters

By leveraging existing camera infrastructure, the system provides comprehensive monitoring without requiring extensive new hardware installations.

Critical Applications Across High-Risk Industries

Manufacturing Environments

In manufacturing facilities, Station Occupancy Monitoring ensures:

- Assembly lines maintain proper staffing levels for safe operation

- Quality control stations are continuously attended

- Machine operation areas have the correct number of operators

- Hazardous process zones maintain minimum safety staffing

The system prevents both safety risks from understaffing and inefficiencies from overstaffing, creating optimal operational conditions.

Construction Sites

On dynamic construction sites, the technology monitors:

- Equipment operation stations requiring certified personnel

- Safety observation posts that must be continuously staffed

- Critical access points needing security presence

- Specialized work zones requiring minimum team sizes

By ensuring proper staffing at these key locations, the system significantly reduces accident risks in this high-hazard industry.

Station Occupancy Monitoring different locations

Station Occupancy Monitoring different locations

Mining Operations

In mining environments, the system provides crucial oversight by tracking:

- Underground monitoring stations that require continuous staffing

- Ventilation control areas needing qualified personnel

- Extraction zones requiring minimum team sizes

- Emergency response stations that must never be left unattended

This vigilant monitoring is particularly valuable in remote or underground locations where supervision is challenging.

Oil and Gas Facilities

For oil and gas operations, Station Occupancy Monitoring enhances safety by ensuring:

- Control rooms maintain minimum qualified personnel

- Drilling platforms have proper staffing levels

- Testing and monitoring stations are continuously attended

- Emergency shutdown stations have required personnel present

The system helps maintain strict compliance with the industry's rigorous safety regulations while optimizing workforce deployment.

Key Benefits Beyond Basic Safety

Enhanced Regulatory Compliance

Station Occupancy Monitoring simplifies adherence to various regulations:

- OSHA requirements for minimum staffing in hazardous operations

- Industry-specific safety protocols requiring attended stations

- Documentation of proper staffing levels for compliance reporting

- Evidence of due diligence for safety management

The system automatically generates comprehensive records, streamlining reporting and audit processes.

Operational Efficiency Improvements

Beyond safety, the technology optimizes operations through:

- Identification of understaffed critical stations

- Detection of resource waste from overstaffing

- Data-driven insights for optimal workforce allocation

- Reduction in downtime from improper station management

These efficiency gains often translate directly to cost savings and productivity improvements.

Comprehensive Safety Analytics

The data provided by Station Occupancy Monitoring enables continuous improvement:

- Historical trends in station staffing patterns

- Identification of problematic stations requiring attention

- Correlation between staffing levels and safety incidents

- Quantifiable metrics for safety program effectiveness

This analytical approach transforms safety from a reactive necessity to a proactive strategic advantage.

Implementation: Seamless Integration

Visionify's Station Occupancy Monitoring system is designed for straightforward adoption:

- Utilizes existing security camera infrastructure

- Requires minimal additional hardware

- Integrates with current safety management systems

- Scales from individual stations to facility-wide deployment

The web-based management dashboard provides intuitive controls for station definition, occupancy parameters, and alert configuration, making the system accessible to safety teams without extensive technical expertise.

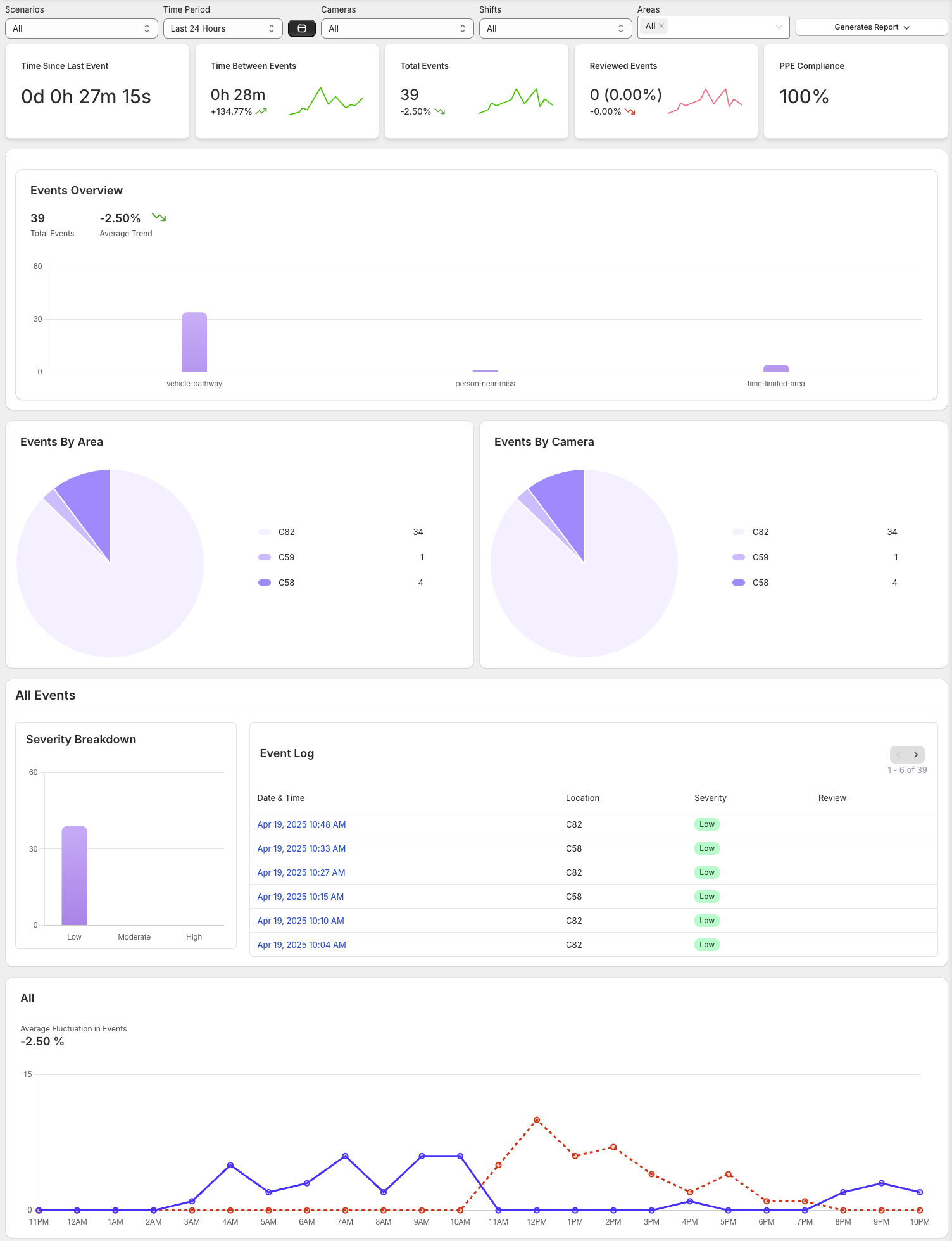

Visionify's Station Occupancy Monitoring dashboard

Visionify's Station Occupancy Monitoring dashboard

Real-World Impact: Measurable Results

Organizations implementing Station Occupancy Monitoring typically experience:

- 30-40% reduction in station-related safety incidents

- 15-25% improvement in operational efficiency

- Significant decrease in compliance violations

- Enhanced ability to identify and address safety gaps

These measurable outcomes demonstrate the system's value as both a safety enhancement and an operational optimization tool.

Conclusion: Transforming Station Safety Management

Station Occupancy Monitoring represents a significant advancement in workplace safety technology by addressing the critical factor of proper staffing at key operational points. By providing automated, real-time enforcement of occupancy requirements, these systems fill a crucial gap in traditional safety approaches.

For organizations in high-risk industries, AI-powered station monitoring offers an effective, efficient solution that enhances safety outcomes while simplifying compliance and improving operational efficiency.

As industrial operations continue to evolve in complexity, Station Occupancy Monitoring provides the proactive, data-driven approach needed to maintain safety excellence while optimizing resource utilization.

Ready to enhance your workplace safety with AI-powered Station Occupancy Monitoring? Contact Visionify today to schedule a demonstration and discover how our solutions can transform safety management at your critical workstations.

Frequently Asked Questions

Find answers to common questions about this topic

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Related Articles

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.