How does Label Checker Solution look for presence of a use-by date?

Key Takeaways

- Food Safety: Use-by dates are critical for consumer safety and regulatory compliance

- Automation Advantage: Vision systems verify labels with greater speed and accuracy than manual inspection

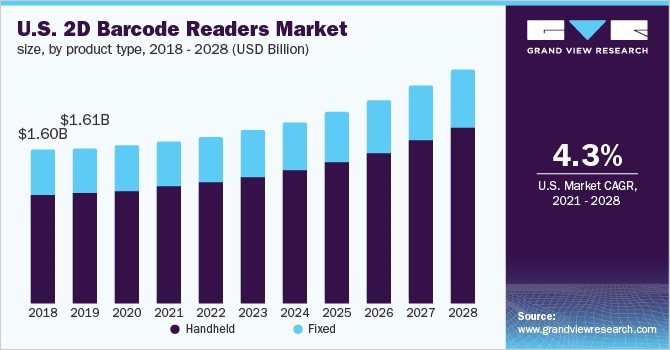

- Market Growth: The global 2D barcode reader market is projected to reach $6.79 billion by 2028

- Implementation Ease: Modern systems offer web-based interfaces for simple configuration

- Comprehensive Inspection: Solutions can verify multiple label attributes simultaneously

The Critical Importance of Date Verification

Use-by dates serve as a crucial safety mechanism in the food industry, particularly for organic and perishable products. These dates inform consumers about when products should be consumed to ensure safety and optimal quality. Without proper date labeling, consumers have no reliable way to determine if food is fresh or expired, potentially leading to health risks and diminished customer trust.

Modern vision systems can verify multiple label elements including use-by dates, barcodes, and product information

Modern vision systems can verify multiple label elements including use-by dates, barcodes, and product information

For manufacturers in the organic food industry, ensuring that every package carries an accurate and legible use-by date is not merely a quality concern—it's a regulatory requirement and a cornerstone of consumer safety. According to Grand View Research, the global 2D barcode reader market, which includes label verification technology, is projected to reach USD 6.79 billion in 2020 and grow at an estimated CAGR of 6.7% from 2021 to 2028, reflecting the increasing importance of automated verification systems.

Understanding Label Checker Solutions

Label checker solutions are compact, multifunctional quality control systems designed to perform comprehensive label inspections at production speeds. These systems combine specialized cameras, lighting, and software to verify various label elements, including:

- Use-by dates: Ensuring presence and readability

- Barcodes: Verifying scan quality and content

- Label positioning: Checking for proper placement

- Label condition: Detecting skewed, folded, or wrinkled labels

- Product information: Confirming accuracy of product details

Modern label checkers employ optical character recognition (OCR) and machine vision technology to read and verify text, even in challenging production environments with high speeds, variable lighting, and diverse packaging materials.

How the Technology Works

Label checker solutions employ several key technologies to verify use-by dates:

1. Image Acquisition

The process begins with capturing high-quality images of each package as it moves through the production line:

- High-Resolution Cameras: Capture detailed images of label areas

- Specialized Lighting: Enhances contrast for better text recognition

- Precise Timing: Synchronizes image capture with package movement

- Multiple Angles: Some systems use multiple cameras for comprehensive coverage

2. Image Processing

Once captured, images undergo sophisticated processing:

- Region of Interest Detection: Identifying where the date should appear

- Image Enhancement: Optimizing contrast and clarity

- Character Segmentation: Isolating individual characters for recognition

- Noise Reduction: Filtering out background patterns and textures

3. Optical Character Recognition

The core of date verification is OCR technology:

- Character Recognition: Identifying individual numbers and letters

- Format Verification: Confirming the date follows the expected pattern

- User-Defined Fonts: Supporting custom or unusual typefaces

- Contextual Analysis: Using expected patterns to improve accuracy

4. Verification and Response

After analysis, the system makes decisions:

- Pass/Fail Determination: Accepting or rejecting packages based on verification results

- Rejection Mechanisms: Triggering automated removal of non-compliant packages

- Data Logging: Recording inspection results for quality assurance records

- Alert Generation: Notifying operators of systematic issues

Implementation Benefits

Implementing a label checker solution offers several key advantages:

1. Quality Assurance

- 100% Inspection: Every package is verified, not just random samples

- Consistent Standards: Objective criteria applied uniformly

- Early Detection: Problems identified before products leave the facility

- Comprehensive Verification: Multiple label elements checked simultaneously

2. Operational Efficiency

- High-Speed Verification: Inspection at full production speeds

- Reduced Labor: Minimized need for manual inspection

- Decreased Waste: Fewer recalls and returns due to labeling errors

- Production Insights: Data collection for process improvement

3. Ease of Implementation

Modern label checker solutions are designed for straightforward deployment:

- Web-Based Interfaces: Simple configuration without specialized programming

- Quick Setup: Rapid commissioning and changeover between products

- Intuitive Operation: Minimal training required for operators

- Flexible Integration: Compatible with existing production equipment

Commissioning and Configuration

One of the most significant advantages of modern label checker solutions is their ease of implementation. Visionify's systems feature:

- Web-Based User Interface: Configure and monitor the system from any networked device

- Guided Setup: Step-by-step configuration wizards

- Visual Programming: No coding required for most applications

- Template-Based Operation: Save settings for different products for quick changeover

This simplicity makes the commissioning process straightforward, even for organizations without extensive vision system experience. New employees can be trained quickly, and the intuitive interface supports rapid troubleshooting when needed.

Application in Organic Food Manufacturing

For organic food manufacturers, label checker solutions address several specific challenges:

- Diverse Product Lines: Easily adapt to different package types and label formats

- Variable Production Speeds: Maintain accuracy across different production rates

- Regulatory Compliance: Ensure adherence to food safety labeling requirements

- Brand Protection: Prevent distribution of incorrectly labeled products

By implementing automated verification, manufacturers can ensure that every package leaving their facility carries the required use-by date, protecting both consumers and their brand reputation.

Conclusion

Label checker solutions represent a critical technology for food manufacturers seeking to ensure product safety, regulatory compliance, and brand protection. By automating the verification of use-by dates and other label elements, these systems provide consistent, reliable inspection at production speeds.

As consumer expectations for food safety continue to rise and regulatory requirements become increasingly stringent, automated label verification is becoming not merely a competitive advantage but an essential component of responsible manufacturing. For organic food producers and other manufacturers of perishable goods, implementing a label checker solution is a proactive step toward ensuring product quality and consumer safety.

This article provides a historical perspective on label checking solutions. While Visionify now specializes in computer vision solutions for various industries, we recognize the continuing importance of automated inspection technologies in ensuring product safety and quality.

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Related Articles

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.