Evaluating the Economic Impact and Cost-Benefits of AI for Manufacturing Safety

See It In Action

AI Safety Monitoring in Action

See how Vision AI automatically detects safety violations in real-time

Example Videos

AI Safety Monitoring in Action

See how Vision AI automatically detects safety violations in real-time

Key Takeaways

-

Significant Cost Reduction: AI safety solutions help prevent accidents that contribute to the $167 billion annual cost of workplace injuries in the U.S.

-

Insurance Savings: Improved safety records through AI monitoring lead to negotiable reductions in insurance premiums.

-

Productivity Gains: Proactive hazard detection minimizes operational disruptions and costly downtime.

-

Compliance Assurance: AI monitoring ensures adherence to safety regulations, avoiding penalties and legal liabilities.

-

Rapid ROI: Most manufacturers see return on investment within 12-18 months of implementing AI safety solutions.

-

Scalable Protection: AI systems provide consistent monitoring across facilities without proportional increases in cost.

Introduction: The Economic Burden of Poor Workplace Safety

Manufacturing environments present numerous safety challenges—from heavy machinery and hazardous materials to high-traffic areas with complex operations. Traditional safety approaches that rely on manual supervision often result in inconsistent monitoring, delayed responses, and human error, creating significant potential for compliance lapses and accidents.

The financial impact of workplace safety incidents is staggering. According to the National Safety Council, workplace injuries in the United States cost $167 billion in 2021 alone, including:

- $47.4 billion in lost wages and productivity

- $36.6 billion in medical expenses

- $57.5 billion in administrative costs

- $13.8 billion in uninsured costs

- $11.7 billion in property damage and other losses

Globally, the International Labor Organization (ILO) estimates that workplace accidents and illnesses cost approximately $2,680 billion annually—about 3.9% of worldwide GDP. Beyond these direct costs, manufacturers face additional financial burdens from increased insurance premiums, regulatory fines, litigation, and reputational damage.

Manufacturing environments present numerous safety challenges requiring constant vigilance

Manufacturing environments present numerous safety challenges requiring constant vigilance

How AI Transforms Safety Economics in Manufacturing

Artificial Intelligence is revolutionizing manufacturing safety by shifting from reactive to proactive risk management. AI-powered solutions continuously monitor workspaces through existing camera infrastructure, instantly identifying safety violations and potential hazards before incidents occur.

Key Economic Benefits of AI Safety Solutions

1. Accident Prevention and Direct Cost Reduction

AI systems continuously monitor for unsafe behaviors, malfunctioning equipment, and environmental hazards. Through predictive analytics and instant alerts, issues like PPE non-compliance, restricted zone violations, and unsafe machine operations can be addressed immediately.

This proactive approach significantly reduces:

- Medical expenses from workplace injuries

- Workers' compensation claims

- Lost productivity from injured workers

- Equipment damage costs

- Administrative costs of accident investigation and reporting

2. Lower Insurance Premiums

Insurance providers recognize the value of AI-powered safety monitoring. Manufacturers implementing these systems often qualify for premium reductions of 10-30% due to:

- Documented improvement in safety metrics

- Reduced frequency and severity of claims

- Evidence of proactive risk management

- Comprehensive safety data collection

3. Minimized Operational Disruptions

When accidents occur, production often stops completely. AI safety systems prevent these costly interruptions by:

- Detecting equipment issues before failures occur

- Ensuring proper machine operation procedures

- Monitoring restricted areas to prevent unauthorized access

- Maintaining appropriate staffing levels in critical areas

The resulting continuity translates directly to improved productivity and profitability.

Worker monitoring safety dashboard

Worker monitoring safety dashboard

Visionify's AI Solutions: Comprehensive Safety and Economic Impact

Visionify offers a suite of AI-powered safety applications specifically designed for manufacturing environments:

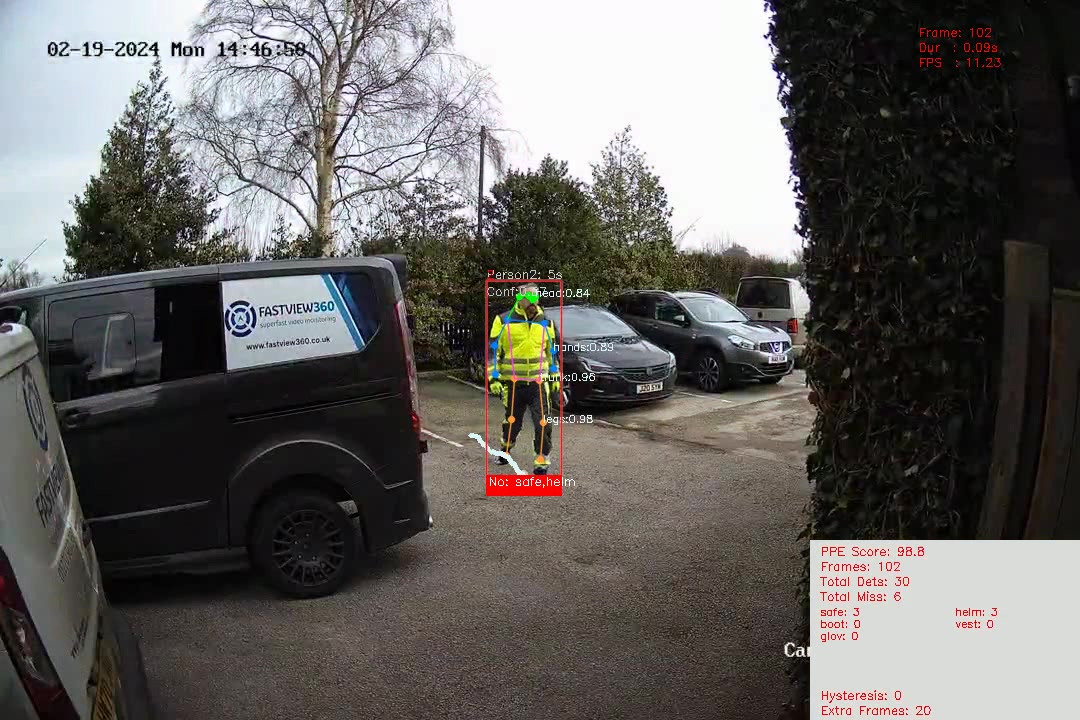

PPE Compliance Monitoring

Automatically detects whether workers are wearing required safety equipment like helmets, gloves, and safety glasses. Real-time alerts notify supervisors of violations, ensuring consistent compliance and reducing injury risks.

Restricted Zone Monitoring

Creates virtual boundaries around hazardous areas, continuously scanning for unauthorized entries. Immediate alerts allow for swift intervention before accidents occur.

Vehicle Pathway and Forklift Safety

Monitors forklift movements and detects risky behaviors or potential collisions. This significantly reduces one of the most common sources of serious manufacturing accidents.

Slip and Fall Detection

Uses sophisticated algorithms to recognize sudden movements or non-responsiveness indicating falls. Instant notifications enable rapid response, potentially reducing injury severity and associated costs.

Worker Count Monitoring

Tracks personnel in specific areas, issuing alerts if staffing levels exceed or fall below safe limits. This prevents overcrowding in busy zones and ensures adequate coverage in high-risk areas.

Pedestrian Pathway Monitoring

Ensures workers stay on designated paths, preventing unauthorized access to restricted areas or zones with heavy vehicle traffic.

The ROI Equation: Measuring Economic Impact

When evaluating the return on investment for AI safety solutions, manufacturers should consider both direct and indirect financial benefits:

Direct Cost Savings

- Reduced workers' compensation claims

- Lower insurance premiums

- Decreased medical expenses

- Avoided regulatory fines and penalties

- Minimized equipment damage

Indirect Economic Benefits

- Improved productivity from fewer disruptions

- Enhanced worker morale and retention

- Strengthened reputation with customers and partners

- Competitive advantage in recruitment

- Better positioning for contract bids requiring strong safety records

Most manufacturers implementing comprehensive AI safety solutions report payback periods of 12-18 months, with ongoing savings continuing to accumulate thereafter.

Vision AI detecting proper PPE usage in real-time on a manufacturing floor

Vision AI detecting proper PPE usage in real-time on a manufacturing floor

Implementation Advantages: Maximizing Economic Benefits

Visionify's solutions are designed for rapid deployment and maximum economic benefit:

Leveraging Existing Infrastructure

The system works with existing CCTV cameras, eliminating the need for costly hardware investments and minimizing implementation expenses.

Scalable Architecture

Solutions can be easily expanded as needs grow, allowing for phased implementation that aligns with budget cycles and prioritizes highest-risk areas first.

Real-Time Alerts Across Multiple Channels

Notifications via email, SMS, and platforms like Microsoft Teams ensure immediate awareness of safety issues, enabling swift intervention before incidents escalate into costly accidents.

Customizable Dashboards and Analytics

Detailed insights into safety trends and compliance data help identify persistent risks and optimize safety investments for maximum return.

Conclusion: The Economic Case for AI in Manufacturing Safety

The financial case for implementing AI-powered safety solutions in manufacturing is compelling. By preventing accidents, reducing insurance costs, minimizing operational disruptions, and ensuring regulatory compliance, these systems deliver measurable ROI while creating safer workplaces.

Visionify's comprehensive suite of AI safety applications provides manufacturers with the tools needed to transform safety from a cost center to a value driver. With customizable solutions that leverage existing infrastructure and deliver actionable insights, manufacturers can achieve both improved safety outcomes and significant economic benefits.

In today's competitive manufacturing landscape, AI-powered safety monitoring isn't just about protecting workers—it's about protecting the bottom line.

This article was published on October 30, 2024, and reflects the latest developments in AI technology for manufacturing safety.

Frequently Asked Questions

Find answers to common questions about this topic

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Related Articles

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.