How Label Inspection Solutions Can Benefit Food Industry?

Key Takeaways

- Regulatory Compliance: Ensures products meet labeling requirements and avoid penalties

- Recall Prevention: Catches labeling errors before products reach consumers

- Brand Protection: Maintains brand integrity through consistent, professional packaging

- Operational Efficiency: Reduces manual inspection costs and production line downtime

- Consumer Safety: Verifies critical information like allergen warnings and expiration dates

The Critical Role of Food Labels

In the food industry, labels serve as more than just marketing tools—they're essential carriers of regulatory information, safety instructions, and product identification. Proper labeling ensures compliance with regulations, communicates vital consumer information, and maintains brand integrity.

According to Datam Intelligence, the global food inspection market is experiencing significant growth as manufacturers recognize the importance of quality control in maintaining consumer trust and regulatory compliance.

When labeling errors occur, the consequences can be severe:

- Costly product recalls

- Regulatory penalties

- Consumer safety risks

- Damaged brand reputation

- Lost retail placement opportunities

Automated Label Inspection Technology

Modern label inspection solutions leverage computer vision technology to automatically verify label presence, position, and quality as products move through production lines. These systems capture high-resolution images of each product, analyzing them in real-time against predetermined parameters.

Unlike manual inspection, which is subject to human error and fatigue, automated systems maintain consistent vigilance throughout production runs, detecting even subtle defects that might otherwise go unnoticed.

Key Inspection Capabilities

Double Label Detection

When products receive multiple labels due to equipment malfunctions, the result can be unprofessional appearance and potential regulatory issues. Automated systems instantly identify products with overlapping or duplicate labels, triggering rejection before they advance further in the production process.

Automated systems can detect when multiple labels have been applied to a single product

Automated systems can detect when multiple labels have been applied to a single product

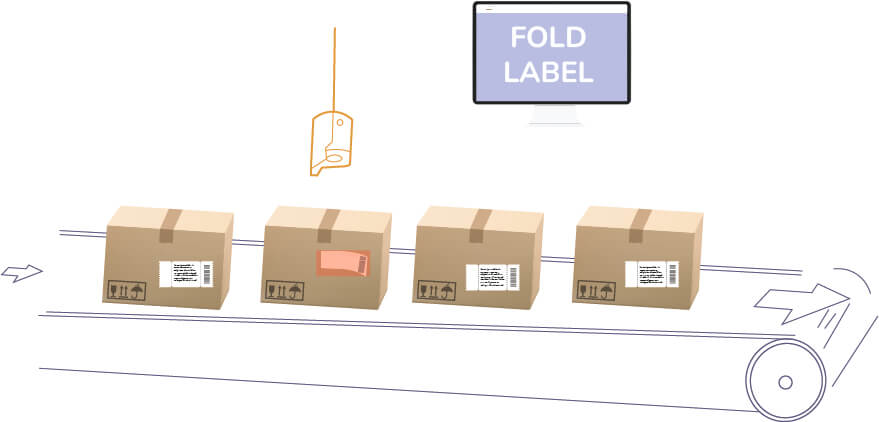

Fold and Wrinkle Verification

Labels that are folded, wrinkled, or improperly adhered may become detached during shipping or display. More critically, folded labels can obscure important information such as allergen warnings or preparation instructions.

Inspection systems verify that labels are smoothly applied and properly adhered, ensuring they remain intact throughout the product lifecycle.

Skew and Alignment Checking

Misaligned or skewed labels create an unprofessional appearance that damages brand perception. Additionally, retail partners may reject products with poorly aligned labels that interfere with barcode scanning or shelf presentation.

Automated inspection verifies proper label alignment according to predetermined specifications, maintaining consistent brand presentation.

Label Pair Verification

Many food products require coordinated front and back labels that must match in design, information, and batch coding. Inspection systems ensure proper pairing, preventing mismatched information that could confuse consumers or violate regulations.

Label Presence Verification

Perhaps the most fundamental check, these systems verify that each product has received its required labels before leaving the production facility. This seemingly simple verification prevents the costly error of shipping unlabeled products to retailers.

Implementation Benefits

Food manufacturers implementing automated label inspection systems report numerous operational benefits:

Reduced Recall Risk

By catching labeling errors before products leave the facility, manufacturers dramatically reduce the risk of costly recalls. A single recall can cost millions in direct expenses while causing lasting damage to brand reputation.

Improved Regulatory Compliance

Automated systems help ensure compliance with increasingly complex labeling regulations, including allergen warnings, nutrition facts, country of origin labeling, and other mandated information.

Enhanced Quality Control

Beyond regulatory requirements, consistent labeling reinforces brand quality perceptions. Inspection systems ensure every product meets brand standards for appearance and information.

Operational Efficiency

Automated inspection reduces the need for manual quality checks, allowing staff to focus on higher-value activities while maintaining superior quality control.

Data-Driven Improvements

Modern inspection systems collect data on common defects, helping manufacturers identify and address root causes in their labeling processes.

Conclusion

In today's competitive food industry, proper labeling is non-negotiable for regulatory compliance, consumer safety, and brand integrity. Automated label inspection solutions provide food manufacturers with reliable, consistent verification that every product meets labeling requirements before reaching consumers.

By implementing these systems, manufacturers can reduce risks, enhance compliance, improve operational efficiency, and protect their brands from the consequences of labeling errors.

This article provides a historical perspective on label inspection technology in the food industry. While Visionify now specializes in computer vision solutions for various industries, we recognize the continuing importance of automated inspection systems in ensuring product quality and safety.

Frequently Asked Questions

Find answers to common questions about this topic

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Related Articles

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.