Case Study: How a Major Power Generation Plant from India boosted its PPE compliance with the help of Visionify's PPE Detection Solution

See It In Action

PPE Compliance in Boiler Room

Example of PPE Violation detected by the system near Boiler Room

Example Videos

PPE Compliance in Boiler Room

Example of PPE Violation detected by the system near Boiler Room

PPE Detection in Hallway

Example of PPE Violation detected by the system in Hallway

Client Profile

Industry: Power Generation

Size: 1,800+ employees

Location: Raipur, India

Capacity: 2,400 MW Thermal Power Plant

Our client is India's largest private thermal power producer and plays a pivotal role in providing electricity through coal-based power generation. The corporation holds a crucial position in the coal-based electricity generation sector in the country. With its expansive power plant facilities and a workforce engaged in high-risk operations, for our client, the safety of its employees is paramount.

Committed to a safety ethos of 'Zero Harm', our client recognized the imperative for an advanced, automated system to oversee Personal Protective Equipment (PPE) adherence at one of its establishments in Eastern India. To address this challenge, they turned to Visionify, for its cutting-edge Vision AI workplace safety solutions.

The Challenge

The Power Corporation faced several challenges in maintaining PPE compliance among its workforce. Their business involves employees working at heights, exposure to electric hazards, loading and unloading operations, and welding activities at different corners, all of which demand strict adherence to safety protocols, especially the use of relevant PPE. Traditional manual monitoring methods proved inadequate, as they could not provide real-time insights and monitor a large number of employees across their vast facilities.

- PPE compliance rates below 40% despite strict safety policies

- 18 reportable safety incidents in the previous year related to PPE non-compliance

- Difficulty monitoring compliance across the vast facility (500+ acres)

- Manual safety checks proving ineffective and inconsistent

- Increasing regulatory pressure following recent industry accidents

- Cultural resistance to consistent PPE usage in certain departments

The plant's Health & Safety Officer approached Visionify with a critical mission: implement a solution that would dramatically improve PPE compliance while creating a sustainable safety culture.

The Solution

After a thorough site assessment, we deployed our Vision AI PPE Detection Solution with the following components:

1. Comprehensive Camera Network

- 40 AI-enabled cameras installed at strategic locations

- Coverage focused on high-risk areas: boiler sections, turbine halls, coal handling plants, and maintenance workshops

- Weatherproof cameras for outdoor areas with extreme temperature conditions

2. Customized AI Detection Models

- Models specifically trained for power plant environments and equipment

- Detection capabilities for:

- Hard hats and safety helmets

- Safety glasses and face shields

- High-visibility vests

- Respiratory protection

- Hearing protection

- Safety gloves and footwear

- Fall protection harnesses

3. Intelligent Alert System

- Real-time notifications to area supervisors via mobile app

- Digital signage displays at entry/exit points showing compliance status

- Automated PA announcements in areas with detected violations

- Escalation protocols for repeated non-compliance

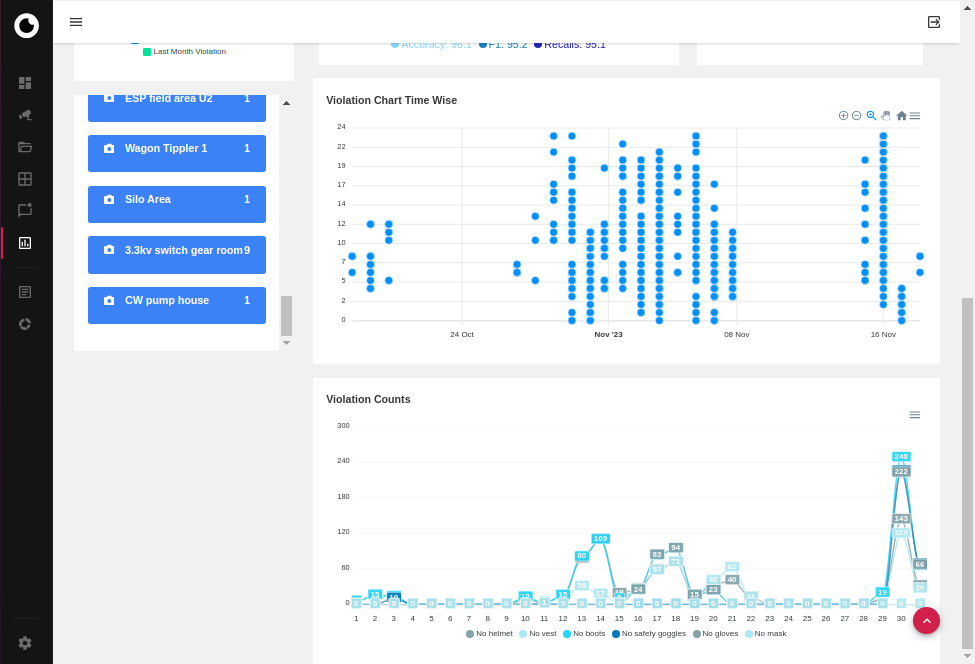

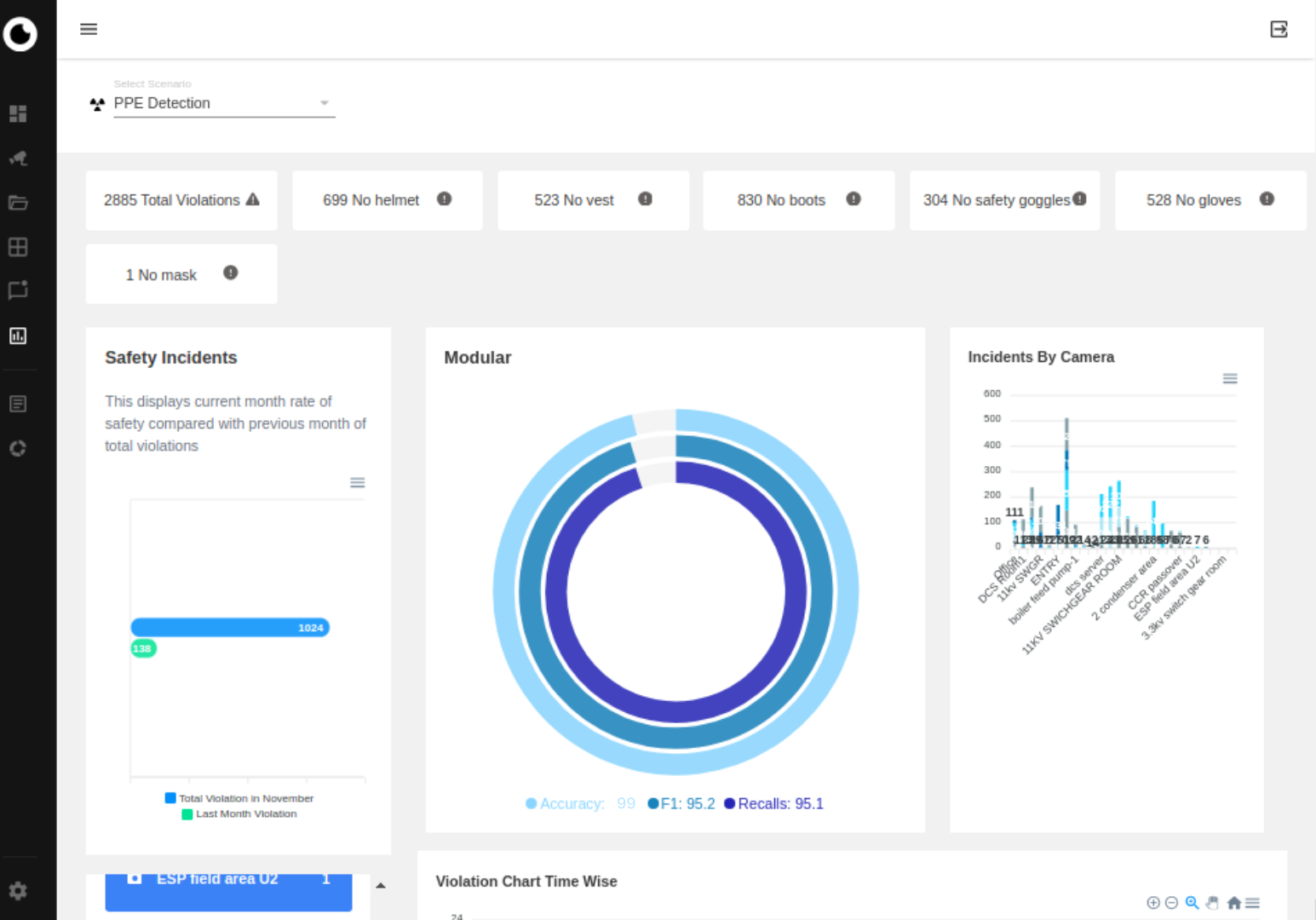

4. Comprehensive Analytics Platform

- Real-time compliance dashboards for management

- Department-wise compliance tracking and benchmarking

- Trend analysis for different PPE categories

- Shift-based compliance patterns

- Integration with the plant's existing safety management system

The management dashboard showing real-time compliance metrics across departments

The management dashboard showing real-time compliance metrics across departments

Accuracy Achieved

The Deployment achieved an impressive accuracy rate of 95% with Visionify's PPE Detection model. This high level of precision instilled confidence in the system's ability to promptly identify and rectify PPE compliance issues.

Implementation Process

The implementation followed our structured approach:

-

Assessment & Planning (3 weeks)

- Comprehensive site survey and risk mapping

- Stakeholder interviews and requirement gathering

- Camera placement optimization

- Network infrastructure assessment

-

Deployment & Integration (5 weeks)

- Phased hardware installation to minimize operational disruption

- Edge computing setup for real-time processing

- Integration with existing security cameras where possible

- Custom AI model deployment

-

Training & Calibration (4 weeks)

- Model fine-tuning for specific environmental conditions

- Staff awareness programs and system demonstrations

- Supervisor training on alert response protocols

- Threshold adjustments to reduce false positives

-

Continuous Improvement (Ongoing)

- Bi-weekly performance reviews

- Model updates based on new PPE types and changing conditions

- Expansion to additional areas based on compliance data

Results

After 10 months of operation, the results were remarkable:

Safety Improvements

- 83% PPE compliance rate across the facility (up from 38%)

- 82% reduction in PPE-related safety incidents

- 100% compliance in highest-risk areas

- Zero serious injuries related to PPE non-compliance

Financial Impact

- ₹12.5M savings in potential liability and accident costs

- 31% reduction in insurance premiums

- ROI of 285% within the first year

- Payback period of just 2.8 months

Other Impacts

- Enhanced Workplace Safety: By proactively identifying and addressing PPE non-compliance, the solution significantly reduced the risk of workplace accidents, making the power generation facilities safer for employees.

- Operational Efficiency: The automated monitoring system saved time and resources compared to manual checks, allowing supervisors to allocate their efforts more effectively.

- Reduced Violations: Trends over a monthly basis showed a consistent reduction in PPE compliance violations, demonstrating the solution's effectiveness in improving safety culture.

Quantifying Progress: Trends Over a Monthly Basis

Over a couple of months since the solution's implementation, Adani Power Limited observed a consistent reduction in PPE compliance violations. This trend underscored the long-term effectiveness of our solution in fostering a safer working environment and reinforcing a culture of safety within the organization.

Additional Benefits

- 9% decrease in unplanned downtime due to safer operations

- Improved regulatory audit outcomes with documented compliance

- Enhanced safety culture with employee compliance becoming self-reinforcing

- Reduced absenteeism related to minor injuries

Implementation Challenges & Solutions

The project faced several challenges unique to the power generation environment:

-

Harsh Environmental Conditions

- Challenge: Extreme temperatures, coal dust, and vibration affecting camera performance

- Solution: Deployment of industrial-grade cameras with specialized housings and regular maintenance protocols

-

Cultural Resistance

- Challenge: Initial employee pushback against "surveillance"

- Solution: Emphasis on education, positive reinforcement, and sharing anonymized compliance statistics

-

Network Connectivity

- Challenge: Limited network infrastructure in older sections of the plant

- Solution: Hybrid edge-computing approach with local processing and scheduled data synchronization

-

Power Fluctuations

- Challenge: Ironically, power quality issues affecting system reliability

- Solution: Dedicated UPS systems and power conditioning for all critical components

Key Success Factors

Several elements were crucial to the project's success:

- Top-down commitment from plant leadership

- Worker involvement in system design and feedback

- Phased implementation allowing for adjustment and learning

- Positive reinforcement through department competitions and recognition

- Integration with existing safety programs and training

- Transparent communication about system goals and privacy considerations

Client Testimonial

"Visionify's model for PPE Detection has revolutionized how we ensure safety across our power generation facilities. With its exceptional accuracy and real-time monitoring capabilities, we have achieved unparalleled levels of PPE compliance. This technology has not only made our workplace safer but has also contributed to our operational efficiency. We are grateful for the partnership with Visionify and its positive impact on our safety culture."

— Rajesh M., Chief Safety Officer

Visionify – Empowering Safer Workplaces Through Cutting-edge Vision AI Technology

Our VisionAI model for PPE Detection provided our client with a powerful tool to ensure 100% PPE compliance within their challenging work environment. Through on-premise deployment, real-time monitoring, and accurate detection, Visionify not only helped improve workplace safety but also streamlined operations.

Our client can now confidently carry out its mission of providing electricity to millions while prioritizing the well-being of its workforce. This successful partnership exemplifies the effectiveness of Visionify's innovative computer vision solutions in enhancing workplace safety.

Conclusion

This case study demonstrates how Vision AI technology can transform safety compliance in challenging industrial environments. By providing continuous monitoring, immediate feedback, and actionable insights, our PPE Detection Solution enabled this power plant to create a significantly safer workplace while improving operational efficiency.

The success of this implementation has led to the company planning deployment across their three additional power plants in India, with expected similar results.

Ready to achieve similar results?

Let us show you how our Vision AI safety solutions can transform your workplace safety.

Schedule a ConsultationSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions