Drip Pipe Drilling Quality Check with AI – Case Study

Client Overview

Our client, a market leader in irrigation equipment and supplies with global distribution, sought to modernize their manufacturing process for drip line pipes. A critical step in their production involves drilling precise holes into pipes according to detailed specifications. Even minor inaccuracies in this process result in wasted materials and reduced product effectiveness.

Computer vision system detecting grooved and non-grooved areas in irrigation pipes

Computer vision system detecting grooved and non-grooved areas in irrigation pipes

The Challenge

The client approached Visionify with several key challenges:

- Precision Requirements: Drilling holes with exact specifications across different pipe dimensions

- Variable Products: Accommodating various tube diameters, wall thicknesses, and emitter types

- High-Speed Production: Maintaining accuracy at production speeds up to 1000 feet per minute

- Quality Verification: Distinguishing between grooved and non-grooved areas of the pipe

- Real-Time Monitoring: Providing immediate feedback for process adjustments

Solution Components

Visionify developed a comprehensive computer vision solution with two primary components:

1. Targeting System

The targeting solution uses computer vision to guide the laser drilling process with unprecedented accuracy:

- High-Speed Capability: Functions effectively at production speeds up to 1000 feet per minute

- Precision Targeting: Maintains accuracy within tight tolerance limits

- Seamless Integration: Works with the client's existing laser drilling equipment

- Adaptive Algorithms: Accommodates different pipe specifications without reconfiguration

2. Quality Control System

The quality check solution monitors the drilling process in real-time:

- Continuous Inspection: Examines every drilled hole for proper placement and formation

- Groove Detection: Identifies and verifies grooved and non-grooved areas of the pipe

- Real-Time Feedback: Provides immediate alerts when deviations occur

- Position Correction: Automatically signals adjustments if the target moves up or down

3. Monitoring and Analytics

Both systems feed into a comprehensive monitoring platform:

- Live Data Streaming: Displays real-time production metrics on deployed monitors

- Deviation Graphs: Visualizes trends and patterns in drilling accuracy

- Statistical Analysis: Tracks key performance indicators for quality control

- Alert System: Stack light indicators signal when processes move out of acceptable ranges

Implementation Results

The computer vision solution delivered significant improvements to the client's manufacturing process:

Performance Metrics

- Detection Accuracy: Over 85% accuracy in identifying grooved and non-grooved areas

- Precision Metrics: Average precision of 62.4% for holes and 61.4% for grooves

- Production Speed: Maintained quality control at full production speeds

- Waste Reduction: Significant decrease in materials rejected due to drilling errors

Business Impact

- Improved Product Quality: More consistent irrigation performance in final products

- Reduced Material Waste: Fewer pipes rejected due to drilling errors

- Enhanced Production Efficiency: Maintained high-speed production while improving quality

- Data-Driven Decisions: Analytics provided insights for continuous process improvement

- Increased Safety: Reduced need for manual inspection in hazardous areas

Technology Approach

The solution leveraged several advanced computer vision technologies:

- Region of Interest (ROI) Processing: Focused analysis on critical pipe sections

- Mask R-CNN: Deep learning model for precise object detection and segmentation

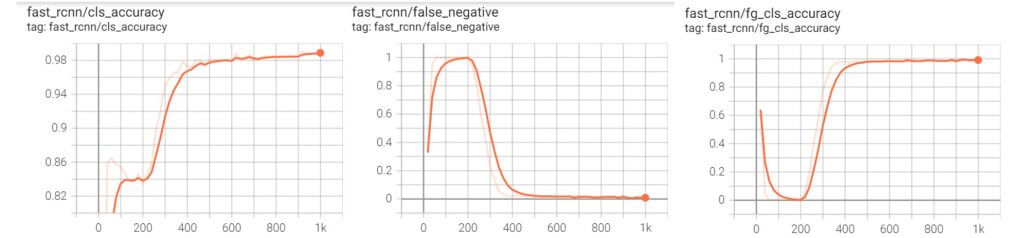

- Fast R-CNN: Accelerated processing for real-time feedback capabilities

- Custom Algorithms: Tailored detection methods for the specific characteristics of irrigation pipes

Conclusion

This case study demonstrates how computer vision and AI can transform traditional manufacturing processes. By implementing Visionify's solution, the client achieved higher quality standards while simultaneously increasing production efficiency and reducing waste.

The success of this implementation highlights the potential for computer vision technology in quality control applications across the manufacturing sector, particularly for products with precise specifications and high production volumes.

This article provides a historical perspective on a computer vision implementation for drip pipe quality control. While Visionify now specializes in computer vision solutions for various industries, we recognize the continuing importance of vision-based systems in manufacturing quality control.

Frequently Asked Questions

Find answers to common questions about this topic

Want to learn more?

Discover how our Vision AI safety solutions can transform your workplace safety.

Schedule a DemoSchedule a Meeting

Book a personalized demo with our product specialists to see how our AI safety solutions can work for your business.

Choose a convenient time

Select from available slots in your timezone

30-minute consultation

Brief but comprehensive overview of our solutions

Meet our product experts

Get answers to your specific questions

Subscribe to our newsletter

Get the latest safety insights and updates delivered to your inbox.