Labeling in the Food and Beverage industry

The Food and Beverage industry remains one of the fastest-growing sectors of the global economy. An ever-increasing population and its consumption demands have seen this sector grow consistently, year after year. With a market size of almost USD 6.2 billion in 2021, this industry is set to cross the USD 8 billion mark by 2025, forecasting a projected growth of 7% CAGR (Source: Research and Markets).

In this industry, great packaging can go a long way. After all, packaging is the first thing to catch a customer’s eye. A crucial aspect of product packaging is labeling. Why? Because labels on food and beverage products contain product-specific data such as origin, date, expiry, amount, or class.

The importance and purpose of labeling becomes even more critical when we consider the beverage industry that heavily relies on bottle packaging. For bottled products like soft drinks, mineral water, and alcoholic drinks, the bottle itself is a package, and it usually does not have a printed layout like a packet of chips, chocolates, and other food products.

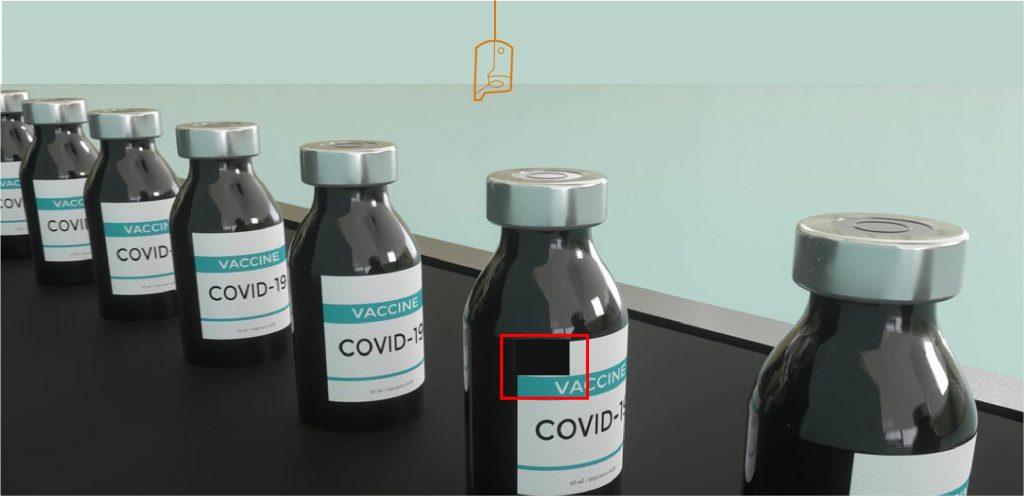

This is where labeling plays a vital role. It carries not only the logo and branding, but also product-specific data. The same applies to pharmaceutical bottles.

Visonify: An asset to the assembly line

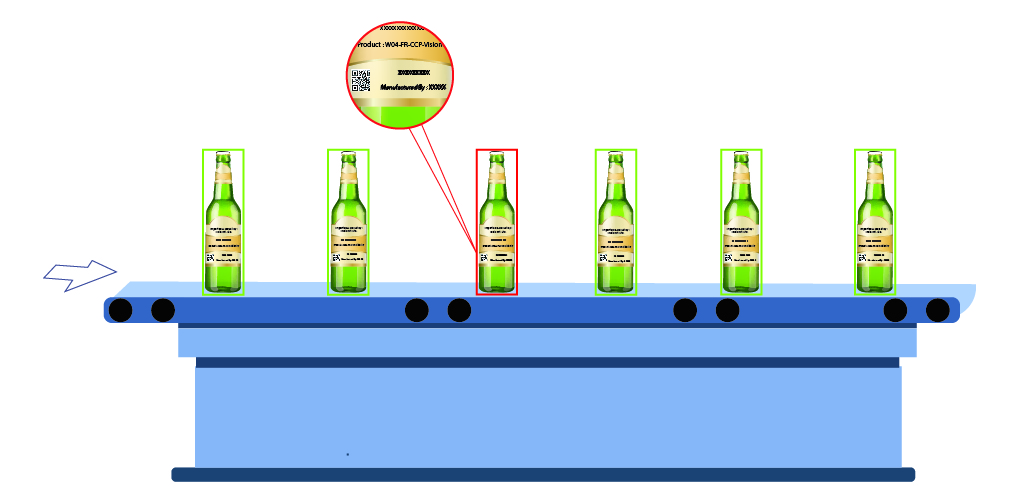

This is where Visionify.ai, which specializes in factory vision, steps in. Our vision systems powered by artificial intelligence and machine learning automatically inspect faults in labeling. This technology helps food and beverage companies in sending out products as originally intended.

The challenge of proper labeling

Even with high-tech equipment and machinery throughout production lines, many companies in the food and beverage industry have to stick to manual inspection and detection of faulty labels. This increases cost and slows down production by huge margins.The most common labeling challenges include:

- Missing labels

- Smudged ink

- Damaged or wrinkled label

- Misalignment

Problems like misalignment become even more common in the beverage industry because of the curved nature of bottles.

What we offer

Mislabeled products can result in recalls and should be detected before they reach retailers. As a result we provide automatic inspection with help of our Smart Manufacturing solutions. Our machine vision tools include high-quality cameras and sensors backed by AI and Machine Learning algorithms to read and prevent faults ideally.

Our solutions also include features like a vision bar for illumination, an encoder wheel to develop line synchronization, a pixel line scan camera, and trigger responses.

Clients’ Feedback

Our clients have always highly acclaimed our services. Our solutions have helped companies in the beverage industry remove errors and produce high-quality products. Furthermore, Visonify.ai has enabled its clients to avoid product recalls, reduce costs and save valuable production time.

What Next?

Are you having labeling errors in your products? The right approach is Visionify.ai’s label-checking solutions. It detects label errors on your product and triggers a reject mechanism. Get in touch with us to receive more information on how our solutions can be deployed on your production line to remove labeling errors.