The food industry plays a prime role in providing ingredients for many other industries. Food safety, hygiene and quality stand out as one of most critical considerations in any capacity of food industry. Essentially machine vision systems can check products to ensure they are defect-free. They can also analyze color and consistency to make sure products meet quality specifications. And inspections take place in real-time so that each product is checked before it leaves manufacturing facility. In this blog you will know how machine vision is revolutionizing the food industry.

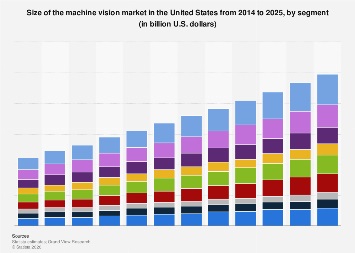

Absolute reports say machine vision software is predicted to be worth US$18470 million by 2028, up from US$9069.3 million in 2021.

It has been over 50 years since first machine vision applications began. Back then technology was used for high-precision assembly and quality control. Fast forward to today and cameras are being deployed throughout food and beverage facilities. Helping to improve processing efficiency, optimize production while maintaining quality, and keep human workers safe by introducing automation.

source: statista

3 ways machine vision revolutionizes food industry

- Tracking and Tracing.

- Safety Inspection.

- Packaging.

Here you can see each way and how they help food manufacturing companies.

Tracking and Tracing

Tracking and tracing capabilities became increasingly important for all companies involved in food production. Machine vision offers a full suite of production lines and state-of-the-art pre-processing to ensure your products’ quality, taste, freshness, and safety in a trusted environment that preserves your brand image and integrity.

Adding to their functionality machine vision systems can track products, packaging, and raw ingredients, throughout production process. This automation allows for a more precise depiction of how much product remains on factory floor. It also makes it easier to quickly determine which batches wheather produced using defective ingredients or defective packaging. Achieving this level of automation nearly impossible without machine vision is one of industry’s biggest challenges.

Safety Inspection

Machine vision solutions use cameras to detect defects in products. In addition they can inspect food in different dimensions during production process. Because machines collect quantitative data on appearance they outperform humans quickly identifying defects.

Accuracy is key to safety inspection and that’s what machine vision delivers. By automating entire process machine vision helps businesses worldwide to ensure high standards of safety and reliability in their food products and reduce possibility of recall or contamination.

Packaging

Packaging is an essential element of most consumer goods. Yet proliferation of package formats has made it one of worst production areas for maintaining quality standards. However recent advances in machine vision have enabled companies to overcome this challenge at high speeds with real-time monitoring and automated sorting.

Packaging inspection comes in various packaging formats including bottles, bags, boxes, cartons and pouches. As your factory increases/decreases its output rate, you need a machine vision packaging inspection system that can adapt to keep up with your changing needs.

Conclusion

Machine vision has been a revolutionary technology in food industry. In past five years we’ve seen dramatic advancements in its applications to everything from sorting tomatoes to detecting rotten meat or fruit, reducing waste, and improving efficiency. Moreover machine vision will become even faster and more affordable in next five years.

Today machine vision has progressed so far that it’s possible to build a factory from parts that come off an automated assembly line with few or no human operations. And used in space applications, for example cameras on Mars rovers and video feeds from satellites.

Visionify.ai’s AI-enabled machine vision solutions automate factories of tomorrow. These solutions make use in anomaly and debris detection and many more. Our solutions decrease manufacturing errors and increase production and are easy to implement and more cost-effective than traditional solutions. Chat with our team to learn more about how we can integrate with your production line.