You want to have some nice, calm, and strong beer in the USA, try the State of Michigan. The state is known in history to be the hub of beer brewing, with a considerable concentration of breweries, microbreweries, and brewpubs.

Research has it that brewing is a millennial old human practice that dates back to approximately over 5000 years ago. It, therefore, makes sense that beer is one of the most consumed alcoholic beverages globally in the history of man. But even with all those years of consumption, the mystery of the brewing process is still a question of whether it is an art or science?

Though many believe it is a product of art, machine learning is gradually disputing this fact and restructuring its development process. Over time, technology has proven to know no boundary in whichever industry. Reinventing the mechanisms and dynamics of functionality in any industry in this era is technology at its best, and this traditional industry– the brewing industry is not an exception.

It takes a significant effort of study and empirical research to develop a technology-based improvement in an industry like brewing. Proffering such adjustments require people like DornerWorks whose bailiwick can navigate through the ebbs of beer brewing.

Problems that needs solving in the brewing industry

- Monitoring the brewing process

Brewing process

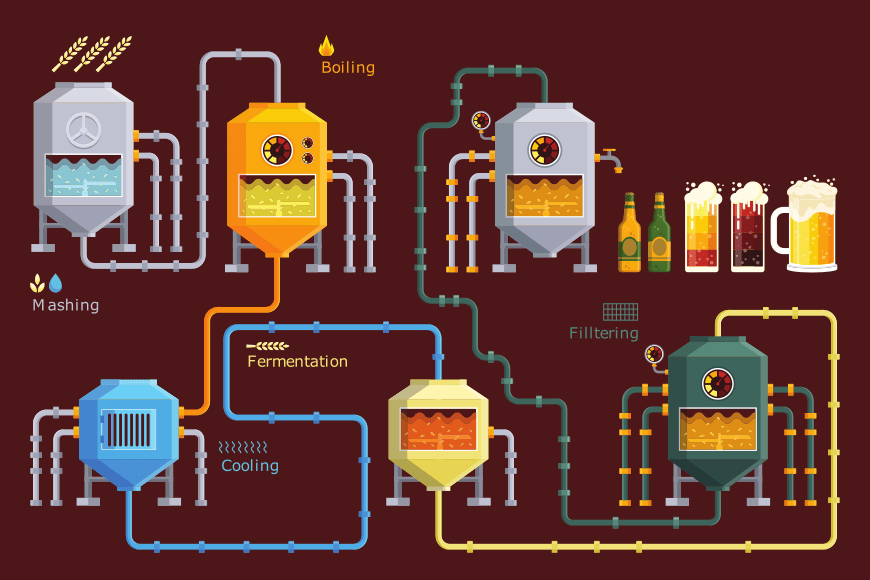

Generally, most of the work in a brewing industry used to be manually carried out until the introduction of digital machines that save the workers some responsibilities.

The analog gauges had to be monitored at all times to ensure optimum temperature and pressure level during the brewing process. The measurement of the variables needed for brewing is very crucial for the end product.

However, keeping the whole process at its optimum with records here and there is too much for human labor. If some of the responsibilities are automated by digital monitors, it will focus on other duties.

The cost of the brewing process would significantly go down when human labor is replaced with machines like computer vision.

Solution to monitoring brewing process

Greg Nowak, a chief engineer at DornerWorks came up with a cloud-based solution capable of simplifying the whole monitoring process. The engineer applied a simple mechanism where a testbench, an analog clock, was used to construct computer visions algorithms. The algorithms would reflect and manipulate the data from an analog gauge in a digital format for reading and printing.

The prototype of this solution consisted of a Raspberry Pi, a camera, and an analog gauge. The Raspberry is connected to the camera as the camera records the readings of the analog gauge. The recordings from the camera are fed into the algorithms of the computer vision which translate the data into a digital format. The data is then forwarded to a cloud service.

The working of computer vision

- Through the camera, the algorithm identifies the dimensions of the face of the analogue gauge i.e. the circle, the center of the circle.

- The algorithm calculates the position of the measuring needle in the gauge

- The algorithm then produces a high contrast image of the gauge and its measurement reading.

Original

Algorithm image

- The computer vision then converts the reading of the position of the needle into a digital scale reading.

The system is programmed to alert the operator with an alarm or a message when the readings hit a particular set threshold. This way, the operator doesn’t have to do manual monitoring of the whole process.

The prototype gave the perfect framework of an automated monitoring solution that produced various monitoring devices for the brewing industry. There is another version of the computer vision that comprises high definition cameras that are capable of recording readings from multiple gauges concurrently.

The next version of the device produces a 3D-printed image of the gauge. The 3D version has advanced features like a fisheye lens camera that is capable of capturing the face of the analog gauge completely in a snap.

- Quality of the beer

Computer vision method in beer quality evaluation

Here is another sector where computer vision has significantly helped the brewing industries. Brewers are known to determine the quality of the beer just by looking at the color of the beer. But imagine testing the quality of each bottle after every production of thousands of bottles in a single file in the bottling line? How long will it take? So many things could go wrong with human labor. Heineken is one of the many brewing industries that has noticed the flaws of human labor in quality evaluation. The Dutch brewing company has its beer-bottling facility in France implementing an R & D machine vision system in quality inspection.

The manual assessment of the quality of the beer can be automated by incorporating systems like computer vision in the brewing process.

Computer vision is a system that can even be applied to determine the quality of beer and even food. The system uses an optical technique mechanism that relies on information collected by the remote sensors; therefore, it doesn’t come into contact with the food or drink.

It is a flawless quality evaluation procedure that has a low-cost budget. The system can therefore boost the brewing production hence improving profitability.

Applications of Computer vision

This technology is implemented in many applications in the world—talk of passenger trains, manufacturing plants, the food industry, refineries, and hospitals.

The system is a necessary addition in the brewing industry that has seen the process seamless and cost-effective.