Factory Vision Solutions

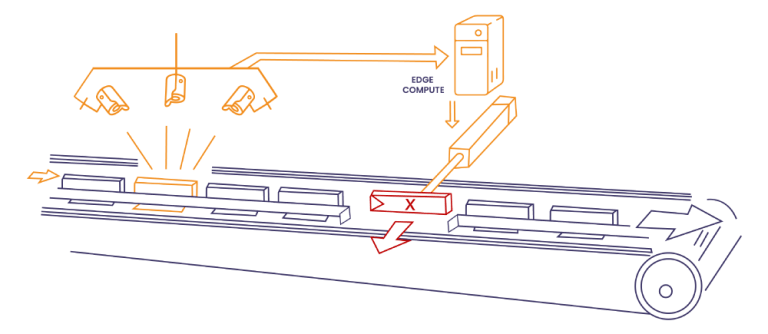

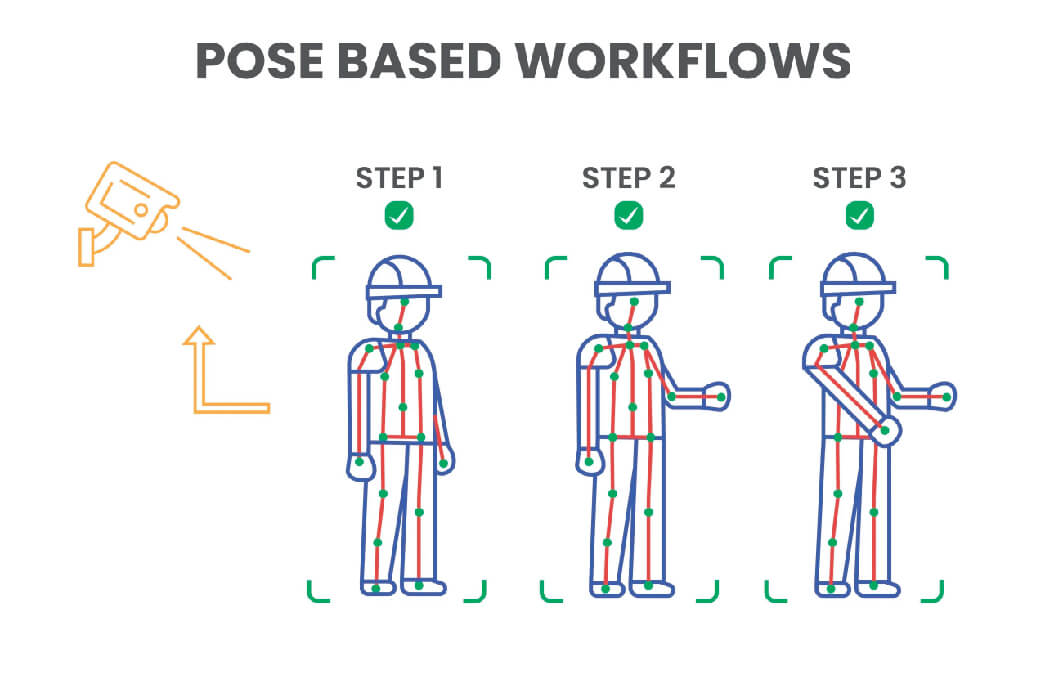

Detect anomalies on objects passing through factory belt.

Models are customizable for your factory needs.

With Visionify’s factory vision solution you get a competitive advantage & improve your bottom line. Contact us today to see how Visionify can help you monitor in real-time and make smarter decisions on products you manufacture.

Prevent manufacturing defects without costing you money. Easily integrate with production control systems to view the status of the objects in real-time.

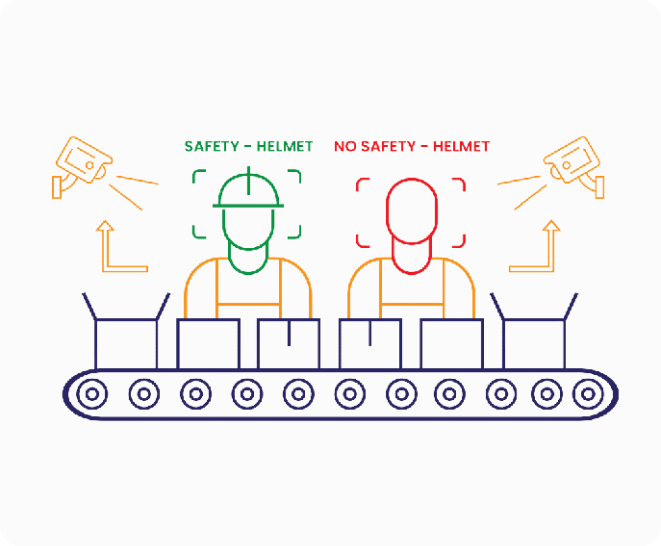

Our Edge Analytics platform runs on the edge of your factory and enables real-time insights for machine monitoring, compliance and safe alerting, employee monitoring, and predictive maintenance.

Visionify team helped build pilot solutions and models for us using both visible and IR cameras. The pilot process was quick and insights this system is generating is invaluable. We are quickly expanding this solution to the rest of the organization.

Dustin Dickinson

Pilgrim's Inc

Real-time inference results and feedback (~30 frames per second processing). Our models are optimized to run on the edge, and our embedded software experts can help build integrations with your factory needs.

We support processing many different types of products. Our Factory Vision solution has been deployed from large poultry processing plants to craft beer bottling plants.

Our team has significant expertise in Embedded system and RTOS development. We can build custom integrations to ring alarms, move machine arms, separate exception objects on different belts etc.

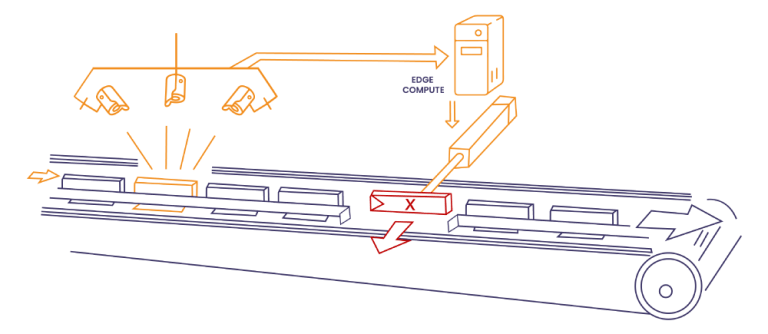

Our NVIDIA optimized pose-detection models can identify a sequence of necessary actions that employees are supposed to perform for assembly. This can build automated safety and compliance procedures customized for your operations.

With our pre-built models, inference engines, and extensible architecture for customized integrations, we can build complete working PILOT solutions with in 4-6 weeks.

Our edge solutions, models, inference framwork and integration are completely Dockerized and are cloud-agnostic. We have deployed solutions with all three major cloud providers: Azure, AWS and GCP.

With Visionify’s factory vision solution you get a competitive advantage & improve your bottom line. Contact us today to see how Visionify can help you monitor in real-time and make smarter decisions on products you manufacture.

No posts found!

Copyright © 2022 – 2023 Visionify.ai