Imagine you have received a birthday gift from your friend, and you are very excited to open it. But unfortunately after opening it, you have found that gift was broken inside the package. This is a result of improper package inspection. This blog talks about package inspection and how it is done using image recognition.

What is package inspection?

Package inspection is inspection of products before being put into shipping boxes or containers. Package inspection ensures that the quality requirements are met and that the items are not damaged throughout the packing process. Therefore, it is recommended for companies that have a lengthy packing method.

The Global Cargo Inspection Market size was estimated at USD 4,035.06 million in 2020 and is expected to reach USD 4,230.07 million in 2021.

Package Scan and Reject Conveyor Belt System with 5 Independent Sensors and Scanners

Why is packaging important?

Every product needs packaging before being dispatched. It offers protection during transportation reducing the risk of damage.

Ways that packaging helps you:

- Prevents damage caused by dropping, crushing, colliding, or vibration.

- Saves product from environmental effects like temperature, humidity, light, filth, and dust.

- Protection from bugs, chemical pollutants, and fungus.

- Protection from theft and tampering.

Packaging helps to sell goods and build brands.

Let’s say you have 6 seconds to impress your customer. In that time your packaging has to tell what your brand is? It has to show how you are different from your competition. It has to convince and advertise your product to the customer. There’s plenty to finish in such a short period. So a package should be inspected properly with image recognition before reaching the store.

Coming to your packaging when you buy anything online. First communication will be the package box or the mailer. If package looks not branded or not well packed your user may not interested in your product and your business may go down.

You have to double-check that every packing decision you make is the appropriate one. Its dimensions and shape, how it opened, colors and images you employ, and, of course, what the text offers regarding your brand and products. Make the time to research and plan. It’s well worth the effort.

That is why packing is so crucial. It promotes your brand, provides data, and sells and protects your goods. When creating your packaging strategy choose parts and equipment that mostly fit (and protect) your products and satisfy your branding.

Which industries use package inspection?

Packaging inspection solutions are essential for maintaining the quality and safety of outgoing products. Broken packaging can impact distributors’ and consumers’ opinions like product quality, safety, and value and lead to product recalls.

source: mosaic data science

Below are a few industries that use package inspection

- Retail

- manufacturing

- airport baggage screening

- food industry

- medicine

How is package inspection done with image recognition?

1. Defining the problem

The process of package inspection starts with technical analysis. The aim is to identify what type of defects the system has to detect.

Questions to include:

- What is packaging inspection Environment?

- Should inspection system be deferred or real-time?

- How often should the inspection system detect defects?

- Do we have any solution to integrate package inspection, or does it require developing from scratch?

- How does the system have to notify about the identified defects?

- Should the system have to maintain detection statistics?

Main Question: Do deep learning model development data already have images of bad and good products and other types of defects?

2. Prepare and Gather data

Machine learning engineers must gather and prepare data to train models before developing a deep learning model. When we talk about Package inspection, the data is all about video records. Where images are processed by visual inspection model with video frames. We have many ways to get data, but the most common methods being used are:

- Processing an existing video from a client.

- Go with open-source videos that apply to your model.

- Collecting data from scratch following deep learning model requirements.

The vital parameter is quality of the video recording. The higher quality video gives high accurate output.

After collecting all the data, we make it ready for modeling, checking anomalies and their relevance.

3. Developing a deep learning model

Selecting a deep learning model for development has limitations in the task, budget, and delivery time.

3.1. Implementing a deep learning service (like Amazon ML, Google cloud ML Engine)

This approach suits when defect detection features align with templates given in selected service. With this service’s budget and time saved, there is no need to create new models. Instead, you have to upload data and give model options according to task the model has to do.

What’s the con? These models are not custom and have limited capabilities given by service.

3.2. Using pre-trained models

It’s an already designed deep learning model that does tasks as we want. So there is no need to develop a model from scratch and it works with a trained model depending on our data.

What’s the con? A pre-trained model is not 100% suitable to complete all our tasks but saves time and money when used for models with large data sets.

3.3 Deep learning model development from scratch

This approach is unique for all package inspection systems. Of course building this model takes more time but the output is worthy.

While developing a package inspection model machine learning engineers use many computer vision algorithms. That includes instance segmentation, object detection, image classification.

We have many factors to consider while developing a deep learning model.

- Image resolution.

- Defect types.

- Many products to inspect.

- Lighting conditions of inspection environment.

- Size of defects and objects.

- What are your business goals?

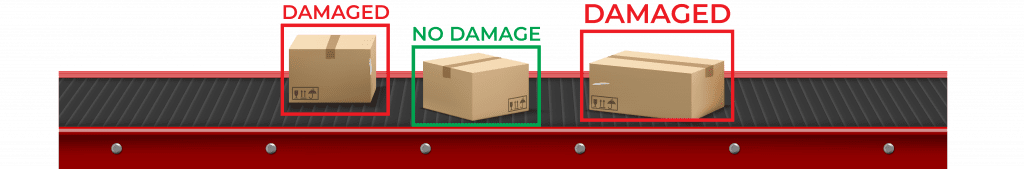

Let’s say we are developing a factory vision solution for detecting anomalies on objects that pass through a factory production belt. We need a practical dataset for accurate visual inspection. The defect categories like damaged package, package without seal, open package. The ideal solution here is to develop a segmentation model from scratch. We can deploy a pre-trained model in some cases.

4. Training and evaluation

The next step after developing the model is to start training model. In this step machine learning engineers evaluate the performance and accuracy of training model. A test data set is more useful here. For example, the test data set for package inspection is a set of video records similar to training model.

Deploy and improve

Before deploying a visual inspection model it is vital to check how hardware and software architectures suit it.

Software

Package inspection software integrates neural network processing, python framework, and web solutions for data transmission.

A vital parameter in package inspection is data storage. We have 3 ways to store data: serverless architecture, cloud streaming, and local server.

Every package inspection process should have a video database. Data storage depends on deep learning model operations. For instance, if the system uses a big data set the ideal method is to have a cloud streaming service.

Hardware

Camera: It is for real-time video streaming examples IP and CCTV cameras.

CPU/GPU: If you want real-time results a GPU is the best choice for image-based deep learning models. We can deploy CPU for package inspection model but not for training. For example, nvidia jetson nano is the optimal GPU.

Conclusion

Image recognition helps a package reach its destination intact and ready to sell. But, you should have a productive and reliable packaging line to get that unique product out of the wrapping and into the hands of potential customers. The future of packaging inspection is here but remember that success relies upon an effective system throughout the entire process.

Factory belts are a fantastic solution for improving production processes. However one of the most common challenges is detecting anomalies on objects passing through the factory belt. With Visionify you can deploy machine vision solutions to create a long-range fixed camera system customized to fit your factory’s particular needs and requirements. Call us today to get a demo about how Visionify can transform your factory vision system.