Many years ago cheese inspection meant manually checking each block of cheese on a long production table. It was only way to spot occasional foreign body in cheese in those days. Thanks to computer vision that detects foreign bodies and differentiates between foreign objects, such as stones and glass, and natural inclusions like salt crystals and seeds.

A well-known challenge for cheese producers is plastic parts on surface of cheese blocks after foil cutting process. To find flaws in a conveyor belt, many factories use a manual inspection process that slows down a conveyor belt. Even so plastic is hard to detect in cheese, and some flaws in cheese are not always noticed.

What is the challenge?

Detecting mold and debris on manufactured cheese moving on the conveyor belt.

Solution

Visionify foreign object detection for any cheese type.

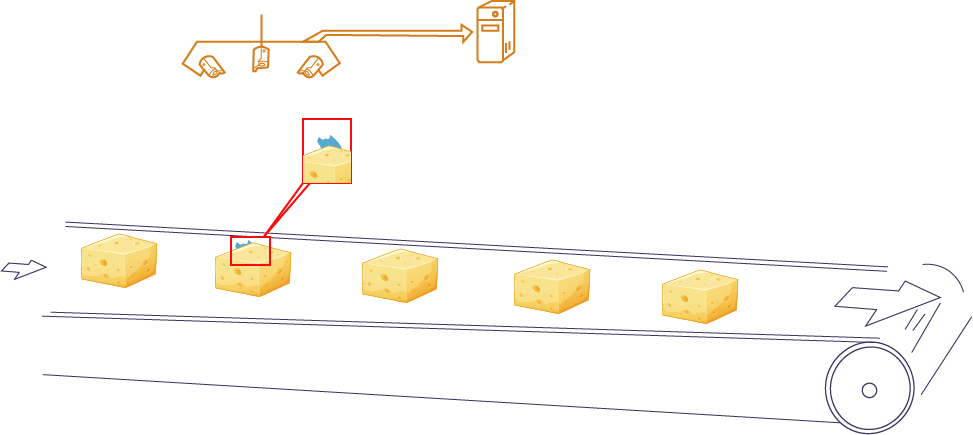

Foreign body detection is possible with tailored vision solutions for reliable, high-speed inspection. They ensure that plastic parts on surface of cheese blocks are detected and removed. Foreign object detectio ensures quality by inspecting all cheese blocks before being cut and wrapped in foil.

Cheese blocks are checked using our solution and cameras to detect foreign objects and mold, preventing mold spores from spreading in production facilities.

Debris detection

In production of cheese foreign bodies can include everything from wood, glass and metal to cardboard, paper and plastic. Detecting even smallest fragments can be complex in a product that varies in shape, color, texture and size. However it can be achieved by our solution in combination with cameras increasingly used for foreign body detection in food production and processing.

You can choose from different configurations to automate inspection of cheese blocks. Inspect cheese blocks from all sides. Bottom inspection is sometimes made using cameras below conveyor belt. Sometimes done by a top camera with a mechanical cheese flipper attached.

Color inspection to check molds.

Color can tell a lot about a food’s quality so manufacturers implement color inspection during food manufacturing process. Our solution can inspect different food products with different colors like baked, not baked, overcooked, etc. You can check if your products are properly baked or precooked with it. This helps companies to group cheese with quality.

It allows you to increase efficiency of your production line and decrease waste.

When mold present on cheese is desirable, it is often not uniform. This kind of color inspection replaces guesswork with precision and accuracy. Mold spots are quickly detected even in small amounts that affect flavor. A color inspection helps find molds that might be missed by human inspectors.

As product color comes under manufacturing, a company can use solution data from processing on finished products to evaluate processing and make adjustments to reduce defects, reducing costs.

The detection of foreign bodies with computer vision has long been a requirement for food industry. For example it is crucial to visually inspect milk products and cheeses in dairy industry. As a result food companies have traditionally invested in expensive detection methods. Computer vision makes it possible to image cheese with high accuracy and cost-effectively using cameras and smart solutions.

Over to you

Are foreign objects is a serious problem in your cheese manufacturing? How you solve it – Visonify’s Foreign Body Detection in Food Manufacturing is the best solution for detecting any type of debris in food products.