Food production industry is one of largest industries in world. Many manufacturing processes and companies are involved in this industry that makes food we enjoy every day. Such processes can take months for research, testing and deployment. Computer vision offers awe-inspiring advances for food and beverage industry.

Companies allow companies to replace humans with higher precision through more efficient, accurate, and consistent automation. It can be leveraged in various ways from improving operations and monitoring food quality to optimizing packaging design, food safety control and maximizing yields.

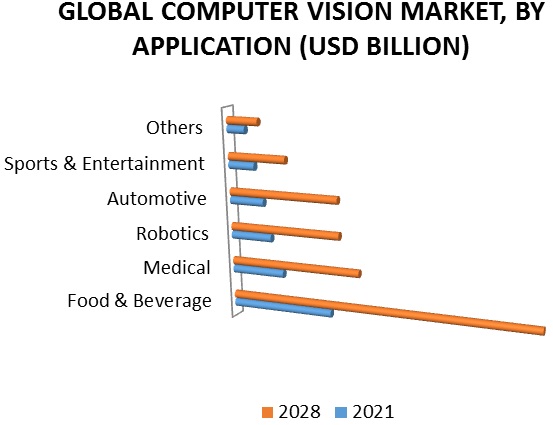

Verified market research says the computer vision market is expected to grow from USD 14.82 billion in 2020 to USD 27.02 billion in 2028.

Source: Verified market research

As demand for quality inspection and automation increases companies are increasingly developing computer vision solutions to detect incorrectly labeled and sub-quality products.

Source: Verified market research

The process of computer vision includes encoding and transmitting images and statistical decision theory applied to visual data. It will be an integral part of 3D imaging in all major industries and is expected to grow into a big market.

| Inspection Goal | Products | Features and Objects | Solutions |

| Detect Food Contaminants | Poultry, meat, bakery, grains, nuts and berries, fruits | Foreign objects | We have to develop a foreign body detection solution with Infrared and thermal cameras to detect foreign objects. |

| Estimating Freshness | Packed products | Food color and temperature | We have to develop a solution that works with Infrared and thermal cameras for detecting food temperature and color. |

| Checking Uniformity and grade by quality | Seafood, bakery, fruits | Topping, baking degree, shape, size | To get accurate real-time results we have to develop a solution trained on different product images with different shapes and sizes. |

3 Ways to apply computer vision to food manufacturing Companies

1. Quality check.

2. Sorting, counting, measuring.

3. Packaging.

Here you can see every way in detail.

1. Quality check

In a food production process quality of each product should be checked so that only high-quality products are delivered to customers. For this purpose use of computer vision systems is increasingly popular in food industry.

Each food company has its own specific requirements for this solution. These often require proprietary data, specialized sensors, and different computer vision technologies. The way to meet these requirements is to customize the software and hardware to each customer.

For instance algorithms for extracting features from images will vary depending on what the object is (e.g., an orange crate) and what’s in the picture (e.g., a grayscale conveyor belt) and background and lighting.

2. Sorting, counting, measuring

While people would have trouble evaluating a fruit’s size, they can generally make a good estimate by comparing its proportions with other fruits they know. Most customers prefer apples that are between 75 and 80 mm in diameter. We can measure diameter of a gorgeous apple in a fraction of a second with computer vision.

A computer vision counting and sorting system can simplify grading fruits, vegetables, nuts, and oysters according to their shape, size, and maturity. It also speeds up sorting by 10 times.

3. Packaging

An automated computer vision visual check of a package’s filling level and labeling can help prevent shortages and food recalls. These solutions can check fill levels in bottles and prevent overfilling and mislabeling.

A visual check can detect packed product freshness by special ink changing its color based on time at a faster pace depending on temperature, this is how machine vision is revolutionizing food industry.

Conclusion

Implementing computer vision technology into a food manufacturing business can enhance efficiency across various departments that companies haven’t ever thought possible. Their management will be able to form a more solid and structured control of their processes, workers’ productivity and even their machinery. With these things in check, companies will achieve outstanding success and growth in their respective industry.

Visionify provides scalable foreign body detection solutions for many industries. The ability to detect a foreign body makes food manufacturing safer for its operator. It also makes it safer for surrounding environment as well. When a foreign body is detected operators can act accordingly to prevent damaging products or damage themselves. You can achieve this by deploying foreign body detection in your manufacturing facility. Call us to get a demo of our solution and our team is ready to help you.